Friday, February 26, 2021

Chip crisis paralyzes the car world

Tesla stops production in US plant

Semiconductor shortages are becoming a serious problem for automakers around the world. Many have already had to cut their production and send employees on short-time work. Now it has apparently also gotten to Tesla. Experts warn: An early relaxation is not in sight.

Automakers around the world see the global semiconductor bottleneck with growing concern. The delivery bottleneck is already having a noticeable impact on many: Tesla also reported difficulties this week. Production in California had to be stopped for two days due to missing components. Production at the Fremont plant started again on Wednesday, CEO Elon Musk tweeted on Thursday.

He did not give a reason for the interruption. But Tesla CFO Zachary Kirkhorn had already announced last month that they would fight the chip shortage by all means. However, difficulties could temporarily arise.

The problem has existed for weeks and is currently affecting the entire auto industry. At Volkswagen, Daimler, General Motors and Ford, too, the situation has already worsened to such an extent that parts of production have had to be shut down. Audi announced an emergency stop for the plant in Ingolstadt two days ago – it is already the second. For the month of March, short-time work and a production stop are on the program again.

The car manufacturers drive on sight

And Ford announced the day before that it wanted to expand short-time work in the group. A company spokesman told the industry newspaper "Automobilwoche" that due to the difficult chip supply in the Fiesta plant in Cologne there would be three more days of short-time work in March, eight additional days of short-time work would be introduced in Craiova in Romania and even 14 extra days in Valencia in Spain . How many vehicles can be manufactured less due to the lack of chips, Ford left open. "The general delivery situation and, depending on it, the production planning remain tense," said the spokesman.

The corona pandemic is to blame for the global shortages in semiconductors. With the first lockdown in many countries around the world, demand for automobiles collapsed drastically in the spring. As a result, the chip manufacturers also cut their production plans. When demand for new vehicles picked up unexpectedly around the world in the summer, chip manufacturers such as Infineon or NXP or contract manufacturers such as TSMC were overwhelmed by the demand.

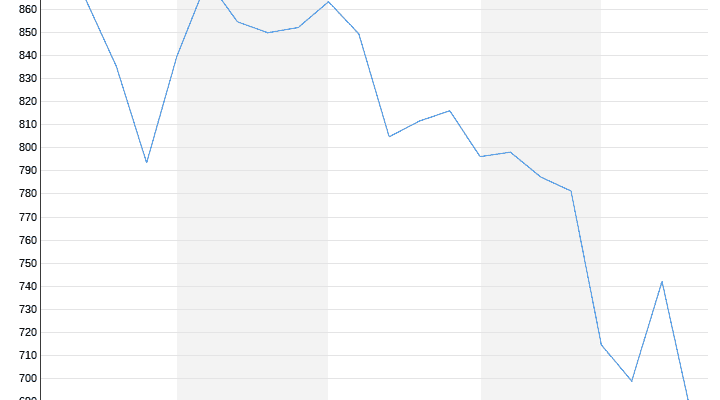

A quick end to the delivery bottlenecks is not in sight: The market experts from IHS Markit warn that the chip bottleneck will probably drag on into the third quarter. According to the IHS, almost 700,000 vehicles will not be produced by the end of the year due to the acute shortage of chips. Infineon boss Reihnard Ploss asked automakers and suppliers to be patient at the beginning of February. "It will take time until additional capacities are available," said Ploss when the quarterly figures were presented. "Many of our customers underestimate the complexity of the supply chain." Infineon is the largest automobile chip manufacturer in the world.

. (tagsToTranslate) Economy (t) Auto Industry (t) Tesla Motors (t) Ford (t) General Motors (t) Semiconductor Industry (t) Infineon (t) Corona crisis