The American company Redwood Materials announces that it is able to recycle batteries at 95%, thus surpassing Tesla, which currently caps at 92%. Led by one of the founders of Elon Musk’s brand, the company specializing in cell enhancement takes stock of its program launched a year earlier.

For years, critics of the electric car have argued that it is difficult to battery recycling as an argument against this motorization. If it is true that it is not free from defects, as we explained in a previous article, it remains overall cleaner than thermal vehicles. Especially since battery recovery solutions are now more numerous.

Optimal recycling

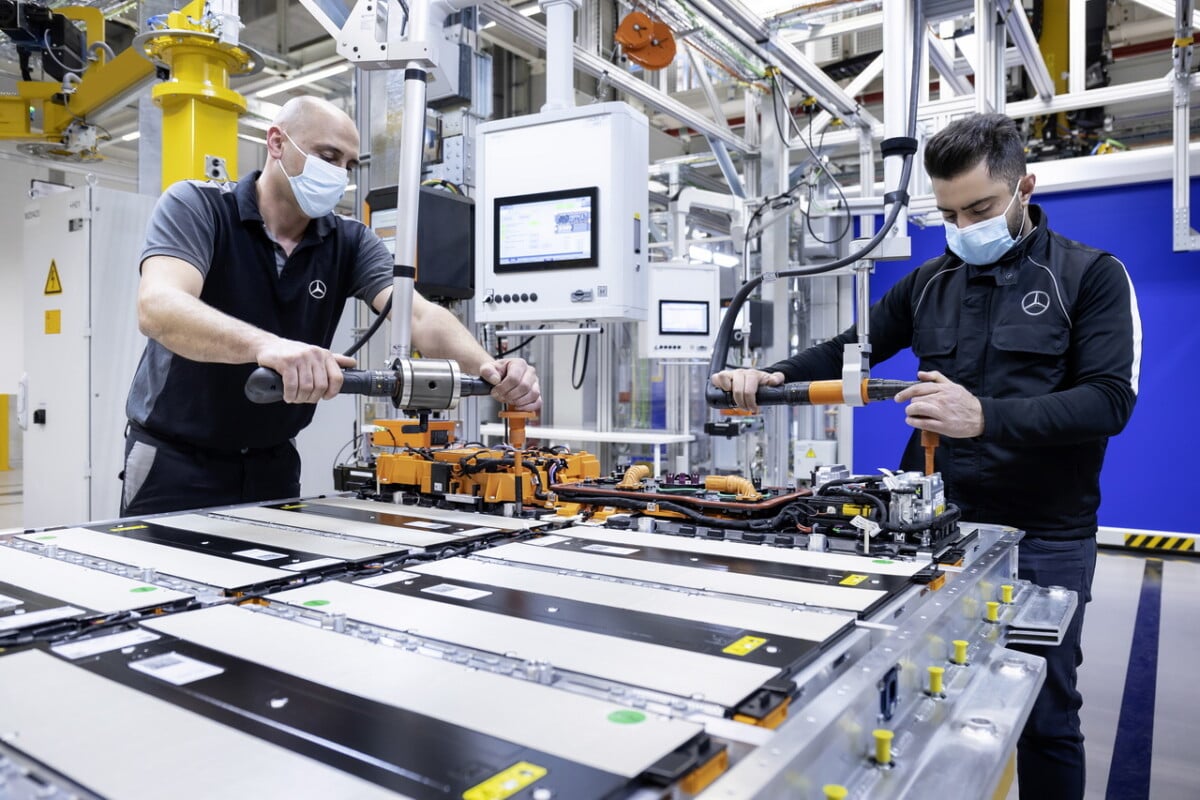

For many years, manufacturers have been racking their brains to find ways to recycle the batteries of their electric cars. The state of these depends on their capacity, expressed as a percentage. If it is above 80%, it can then be reconditioned and used in another vehicle. If not, it is then dismantled and allocated to other uses.

This is exactly what Redwood Materials is working on. It is an American company created in 2017 by JB Straubel, one of the co-founders of Tesla and having worked for 16 years for the manufacturer, now led by Elon Musk. The firm is specialized in recycling batteries from electric cars and launched a year ago an extensive experimental program aimed at improving the revaluation of these packs.

On its site, the company announces today the results of this experiment, and they are rather encouraging. She explains that she succeeded in recover no less than 1,268 end-of-life batteries, coming from 19 models of electric and hybrid cars, working hand in hand with dealerships or scrapyards in California. Among all these packs, less than 5% were “ damaged, defective or recalled“, and therefore unusable.

These accumulators are a mix ofold NiMH chemistry (nickel-metal hydride), notably used on Toyota Prius and other Honda Civic hybrids as well as newer lithium-ion technologies. This is the case of NMC (nickel – manganese – cobalt) or LFP (lithium – iron – phosphate) batteries. The proportion of recycled batteries should then increase considerably, since it is currently the most widely used solution, pending the development of alternatives to sodium or solids.

A new life

Lithium batteries already represent 82% of packs recovered by Redwood to be transformed. Thus, the company claims to be able to upgrade batteries to 95%, exceeding Tesla. In a report dating from 2021, the American firm claimed to be able to recycle up to 92% of materials. Which is already great. For its part, Volkswagen wants to go further and has launched a project to recycle batteries almost infinitely in the future.

But then, what is the fate of these packs once recovered? At Redwood Materials these are dismantled and the materials are used to manufacture new components for other batteries, such as cathodes or anodes. A gesture for the environment, but not only. Indeed, the government now reserves the granting of its tax credit on electric cars only to those that are manufactured in the United States and whose battery is also sourced locally. Which can therefore be the case with this solution.

Thus, customers will pay less for their electric car thanks to this innovation, which makes it possible to reduce dependence on China. However, this technique is still very expensive, mainly due to logistics. To recycle batteries on a large scale, you have to pick them up everywhere and transport them. However, solutions are possible, such as increased collection volumemaking it possible to reduce logistics costs and make them profitable.

Some manufacturers are working on other solutions, such as Suzuki, which announced in May 2025 the development of technology using the batteries of its cars to power streetlights in Japan. An alternative also implemented by Nissan, which had done the same with a Leaf accumulator in 2018.

Our colleagues from Numerama are launching Watt Else, their newsletter dedicated to the mobility of the future. Sign up here to make sure you get the first issue!