Contents

Digitec, Brack and others are automating logistics for more efficiency. For the benefit of the employees?

“Set up the assembly point,” says Florent Hajdaraj, apparently to himself. But his high-tech glasses listen to him. She shows him his tour on a mini display. He has to collect twelve orders in the racks of the Competec logistics center in Willisau, to which online retailer Brack belongs.

The time around Christmas means peak season for online retailers. Hajdaraj travels up to ten kilometers in a day to compile articles.

There is a risk that those wearing glasses will collide because everyone is looking at their display. But there have been no major injuries in crashes, says Hajdaraj and laughs.

On the display, Hajdaraj sees the storage compartments and items he is looking for. The glasses make him more efficient: “They optimize the walking path so that we don’t run all over the place.” He also makes fewer mistakes. If he scans the wrong item, the glasses will notify him.

An efficiency gain of a few percent

Working with glasses takes some getting used to, he admits. You have to constantly look up and down at the display. That was a bit difficult at the beginning.

The high-tech glasses from Brack in use

“Better, but tough on the head,” is how logistics employee Vanessa Lopez comments on the whole thing. She only works for one hour at a time with the support of glasses.

Technology is a means of relieving employees.

Employees have the choice of whether they want to work with or without glasses, says Thomas Gasser, Managing Director of Competec Logistik. He sees only advantages in technological support: “It guides you better and makes the work easier.”

«The pressure in logistics is always high. The technology is a means of relieving and supporting employees,” says Gasser. For the company, the efficiency gain amounts to a few percent. He therefore speaks of a win-win situation.

Robots are setting the pace at Digitec Galaxus

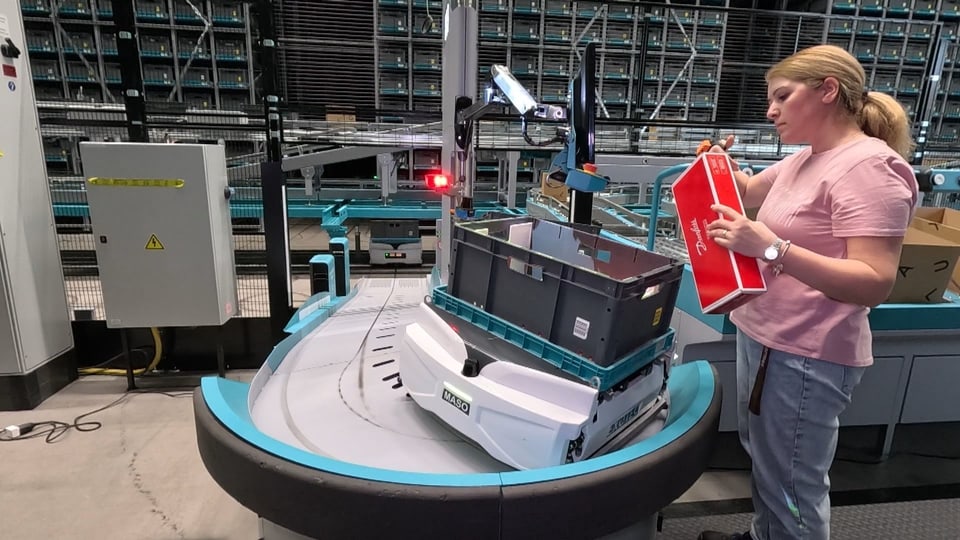

The latest achievement in the Digitec Galaxus logistics center in Wohlen, Aargau are 200 robots – highly efficient warehouse helpers. They scurry around the hall and climb huge high-bay towers.

Within two minutes they can pick up any of the around 100,000 different items and bring them to the stations where logistics employees process them and place them in boxes.

Legend:

In the new Digitec Galaxus logistics center, new robots bring every item to the employee within two minutes.

SRF / Harry Stitzel

More technology means more efficiency, confirms Philippe Marty, head of logistics development at Digitec Galaxus. “In the best case scenario, the employee never has to wait for a product, but rather it is always delivered seamlessly so that we always have our workstations well utilized.”

The company says that the pressure on employees does not increase with faster robots. The volume targets remained the same. But the work is also so strict. “You are on the move all day long. “You sometimes notice it in the evening, but that’s part of it,” says an employee in the robot hall.

The staff feels the cost pressure

The staff is very much affected by technological changes, says e-commerce specialist Darius Zumstein from the Zurich University of Applied Sciences (ZHAW).

«Competition in online retail is increasing, prices and costs are rising, and margins are coming under pressure. Online retailers also have to pass on this pressure, including to their staff.”

This could also mean that employees work faster or that fewer staff have to process the same amount. Zumstein doesn’t name any specific companies.