- Reuse all the floors, without changing anything…

- A design on the borders of science fiction

- It makes or breaks every week

- The competition isn’t there either!

- Money and tests

Even if the sector of “ NewSpace » American is teeming with start-ups dedicated to new launchers, few of them have a goal as advanced as Stoke Space. With a design prepared from the drawing board to be quickly reusable and a team ready to test each new thing… Will that be enough?

Andy Lapsa’s path seems more coherent than many others to co-found an American “NewSpace” start-up. After his engineering studies, the young man joined a virtually unknown company in 2009, Blue Origin. He worked there on rocket engines, in particular the BE-3 and the BE-4, and spent ten years of his career there. Ten years during which Blue became an American aerospace giant… And yet Andy Lapsa faced a dilemma, because he found that the giant founded by Jeff Bezos was not taking the path of audacity and innovation quickly enough. innovation.

Above all, convinced that the technique is available to finally move on to 100% reusable launchers, he leaves Blue Origin. Should you work with his former colleague Tim Ellis, who founded Relativity Space? The only company that meets all of Andy Lapsa’s criteria is SpaceX, but he doesn’t want to come out wrung out like many of his acquaintances. Also, SpaceX should not have a monopoly on reuse: in 2019, he co-founded Stoke Space with Tom Feldman.

Reuse all the floors, without changing anything…

The concept is as simple as it has been heard many times in recent years: a two-stage launch vehicle, designed to be fully and regularly reusable, with as little work as possible between shots to orbit. Easy, right? Imagine that if no one is doing this today, it’s for a good reason. : with the exception of the STS shuttles (which were overpriced and required extensive dismantling between each flight) and the Crew Dragon capsules (which are not to be considered as rocket stages), the objects which go into orbit are not not often recovered or reused. The constraints are incredible, between the management of heat and plasmas generated by the atmosphere, guidance, braking to land on the ground, the materials that must resist, remain waterproof while being cooled, etc.

Made up of a small team of 5 people between 2019 and 2021, Stoke Space is tackling the problem by working solely on a reusable second stage, simulation after simulation. And the solution they chose stands out in the landscape.

A design on the borders of science fiction

First of all, Stoke Space chose a bell or teardrop shape for its upper floor. Which means it will come back through the atmosphere “down and forward”. On the advantages side, it is practical because the upper part can be dedicated to payloads (satellites, vehicles, others), open and close while maintaining a very aerodynamic shape. In addition, there is no need to compensate for the mass of the engines at the bottom, and the pressurization of the tanks always goes in the same direction, with even a natural settlement during atmospheric braking. The downside, however, is the engine design. Stoke Space plans first a removable shield, then removable motors capable of retracting under the shield, before settling on a design with the motors, in a circle, around the shield. It remains to be seen how to cool the latter to combat both friction and the heat produced by the rocket engines.

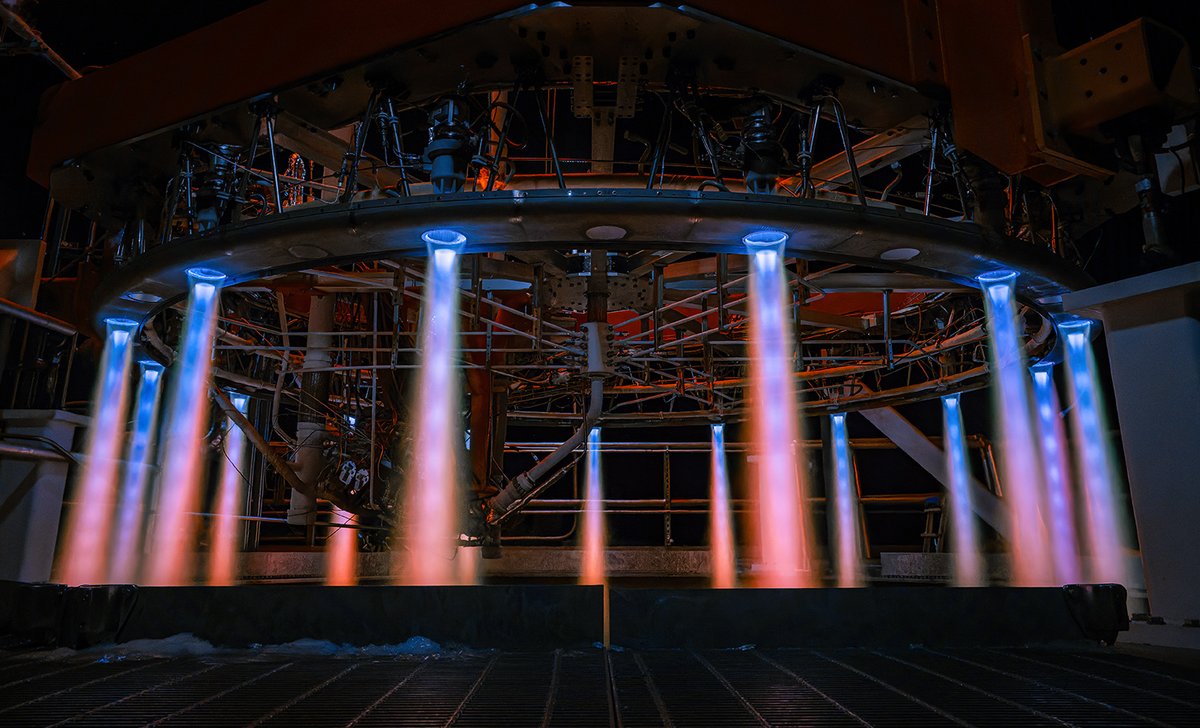

But thanks to simulations, the solution adopted is quite original: multiple small motors in a circle can take advantage of the shield like a virtual nozzle (it’s a bit like the concept of the aerospike) while protecting it by their action during the return and braking through the atmosphere. Andy Lapsa is well aware, with his team which grows to 75 people at the end of 2021, that the concept is quite crazy. But he decided to apply the same method as SpaceX, with an iterative design.

Does it work in simulation? They build it, and quickly, even if it means making mistakes. Then it’s time to fire, and anything that fails is quickly corrected for the next time. Here we go again. Enough to also work on the costs of the materials involved, and the manufacturing processes.

Stoke Space chooses, as with the Starship, to work with steel. Then goes back and forth over this multi-engine concept, to finally choose a single central rocket engine (turbopumps, cooling, supply) and 30 nozzles distributed around the perimeter of the shield. Thirty, no less! Each is fixed, and it is with the variations in thrust that Stoke hopes to control both the injection into orbit, but also the return and landing of the rocket on Earth. Terribly ambitious.

It makes or breaks every week

Rather than technical choices, the key element of Stoke Space’s notoriety, which has continued to rise since 2022, is being a start-up focused on propulsion and its iterative approach. As a result, many observers were able to discover the company during its circle engine tests at the Moses Lake test site, not far from Seattle.

And there were hours of tests! First with elements with questionable welds, breakages, then more serious thrust tests, before the assembly of a steel upper stage prototype, whose resemblance to SpaceX’s very first “flying tank” for Starship immediately struck the general public. It took two examples (the first did not really hold up to pressurization) and dozens of hours on the test bench for a prototype to take off on September 17, 2023 to an altitude of up to 10 meters and then land. laid. But all this, in less than a year. In the last quarter of 2023, the company redirected its efforts on the first stage of the rocket, which is now called Nova and which targets a carrying capacity of 5 tonnes towards low orbit. All while being reusable every day?

The competition isn’t there either!

Obviously, this is not credible at first, especially since the company is not ready to launch its rocket in 2024. However, we should still see more equipment on the test bench, in in particular the engine section dedicated to the first stage, with its 7 reusable engines powered by methane and liquid oxygen. Stoke Space explains that it wants to go faster than its direct competitors, most of whom already have experiences (conclusive or not) with smaller launchers.

Relativity Space and its Terran R, Rocket Lab with Neutron, SpaceX and its 10 to 12 Falcon 9 takeoffs each month, needless to say that Andy Lapsa will have a lot to do with his teams to stand up to them. However, the competition to design and produce a reusable upper stage is still very open. There is no evidence today that Starship will be able to operate regularly and without incident with its thousands of thermal tiles or that Relativity and its 3D printed rocket have a more competitive approach.

Money and tests

For Stoke Space, the material approach and the tests have generated more than curiosity: investors are there. After an initial fundraising of $9 million in 2021, then $65 million in 2022 (including Bill Gates’ investment fund), Stoke Space closed a new “round” of financing with $100 million in October 2023. Enough to break equipment until the first flight, according to the entrepreneur. Stoke Space took the opportunity to expand its premises in Kent (right next to Blue Origin) and continues to poach talent with a “grain of madness”.

In any case, given their rapid progress, Stoke Space is definitely a company to keep an eye on in 2024. And do you think they have the right approach?

3