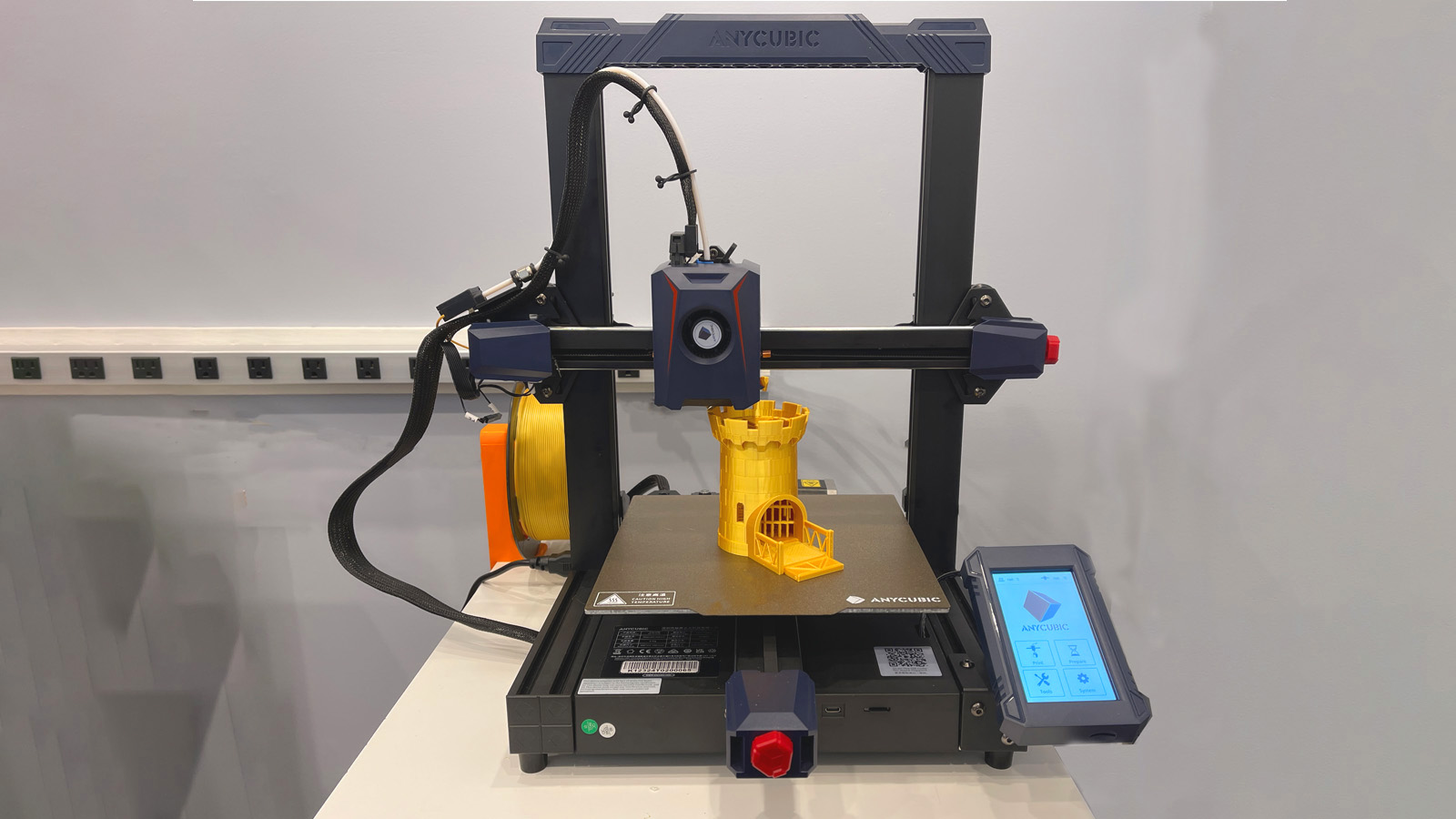

There’s a commonly accepted aphorism when it comes to product marketing: “Fast, cheap, or good: pick two.” With this Anycubic Kobra 2 3D printer, however, you get all three!

This printer is surprisingly fast, relatively inexpensive (at least compared to other printers in its class), and produces surprisingly clean prints.

The Anycubic Kobra 2 is an FDM (Fused Deposition Modeling) 3D printer, which means that it uses melted extruded filament to build objects layer by layer. The other common type of 3D printer on the market is the resin (or SLA for stereolithography) printer. It uses a liquid resin that hardens by exposure to light, also layer by layer.

The difference between FDM 3D printers and SLA 3D printers

Typically, you can build larger, sturdier parts with a filament (FDM) printer, and smaller, more detailed parts with a resin (SLA) printer. If you are building a shelf support, then it is best to use a filament printer. If you want to make a tiny figurine for a diorama, opt for a resin printer.

The Kobra 2 printer uses a heated extruder to melt filament and lay down layers on a build plate. It is at the extruder that we begin to see the features that allow the Kobra 2 to print so quickly.

The extruder is direct drive: it pulls the filament directly into the hot end. This allows the printer to better control the movement of the filament compared to printers whose gear mechanism is located some distance from the extruder.

The proof by the test

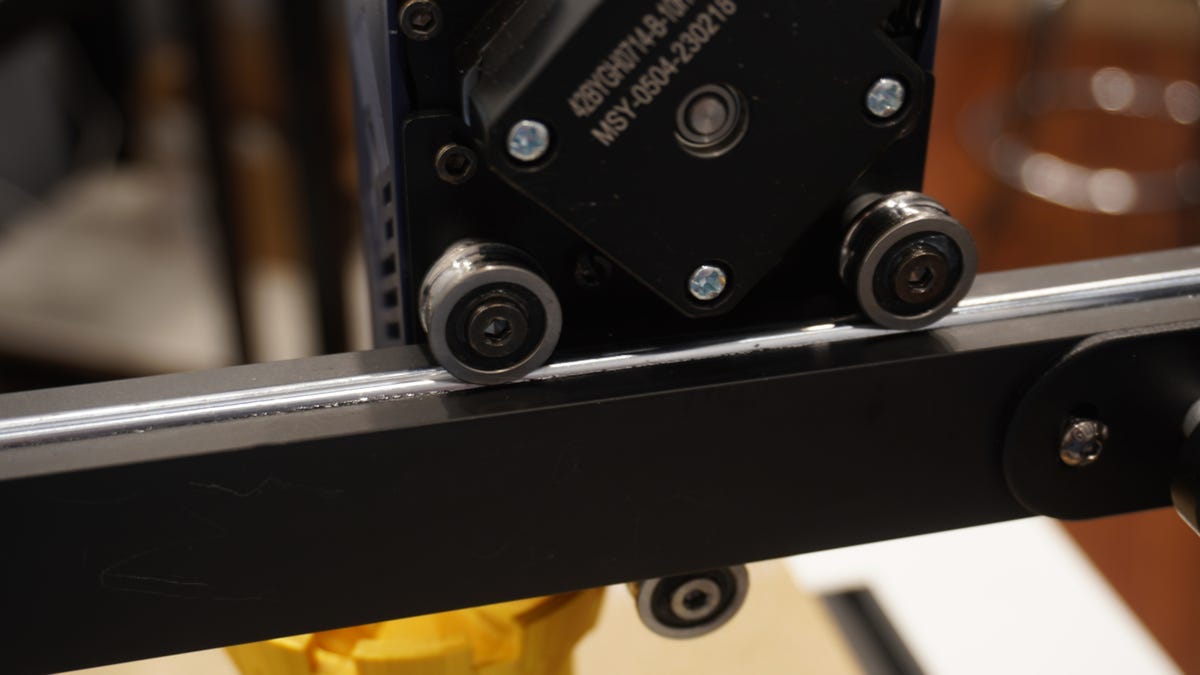

Faster printers tend to use this remote push mechanism because it makes the gantry lighter and therefore less subject to inertial forces. But the Kobra 2 uses sturdy metal wheels to support the entire extrusion mechanism, so they don’t wear out after heavy use.

David Gewirtz/ZDNET

It also uses two lead screws, which move the gantry up and down evenly, although it’s worth noting that the two lead screws are coordinated by a rubber belt, rather than another metal piece. . Despite this, the system works.

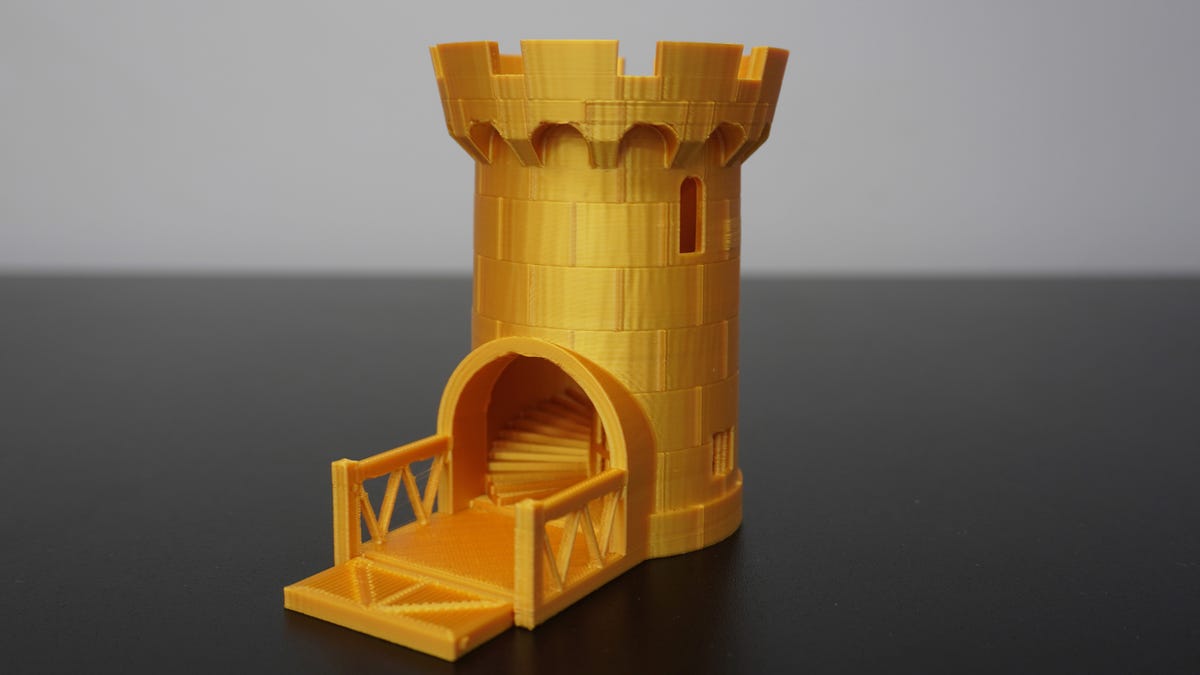

The bottom line is whether the printer prints faster and maintains print quality. And that’s the case! Look how pretty this castle is.

David Gewirtz/ZDNET

Execution speed makes the difference

This is where the speed of execution makes the difference. I printed the castle on Anycubic’s Kobra 2 in 4 hours and 30 minutes. On the Anycubic Vyper, it took 7 hours and 26 minutes. On the Creality Sermoon D1 it took 6 hours and 52 minutes, and on the Ultimaker S5 (over $6000) 7 hours and 43 minutes. All four used print settings of 10% infill and 0.2mm layer height, and have a 0.4mm nozzle.

Here is a final product of the Anycubic Kobra 2. David Gewirtz/ZDNET

Without any special settings, the Kobra 2 was about 30-45% faster than other printers. Anycubic claims a 5x speed improvement which is possible. Firstly with a lot of settings and secondly compared to a very poorly configured comparable printer.

The line running through the fender is the only flaw in all the prints I’ve done on this printer. And yet this dragon is particularly difficult to print for an FDM printer. David Gewirtz/ZDNET

Even so, a 30-45% speed increase right out of the box with the default configuration is impressive and time-saving.

At 250 x 220 x 220mm, the build volume is slightly smaller than the Anycubic Vyper I’ve tested before. At 310 €, it is about the same price. In fact, the feature list (beyond print speed) of this printer at this price is impressive: auto-leveling, removable print surface, filament out sensors, power failure recovery current, and an LCD touch screen to control everything.

Source: “ZDNet.com”