Researchers at the Fraunhofer Institute in Germany are currently working on a large project aimed at recycling end-of-life electric car motors. The goal: to establish a complete diagnostic and revaluation process in order to maximize their lifespan and reduce the use of rare and polluting materials.

Although there are more and more electric cars on the roads, there are still many detractors of this engine. And their arguments are varied, between the price too high, the autonomy too low or even the disappearance of the pleasure of driving. Criticisms which are less and less relevant today. Some also point out difficulties relating to recyclingwhich would make cars more polluting.

An interesting project

Over time, however, we see that this argument is less and less true. Because if the electric car is not 100% clean, the question of battery recovery has now been resolved. Many companies are in fact capable of recycling used batteries, whether due to excessive lifespan or following an accident. Depending on the state of the latter, it may in fact be decided to reuse it in a vehicle or extract its components to make a new one.

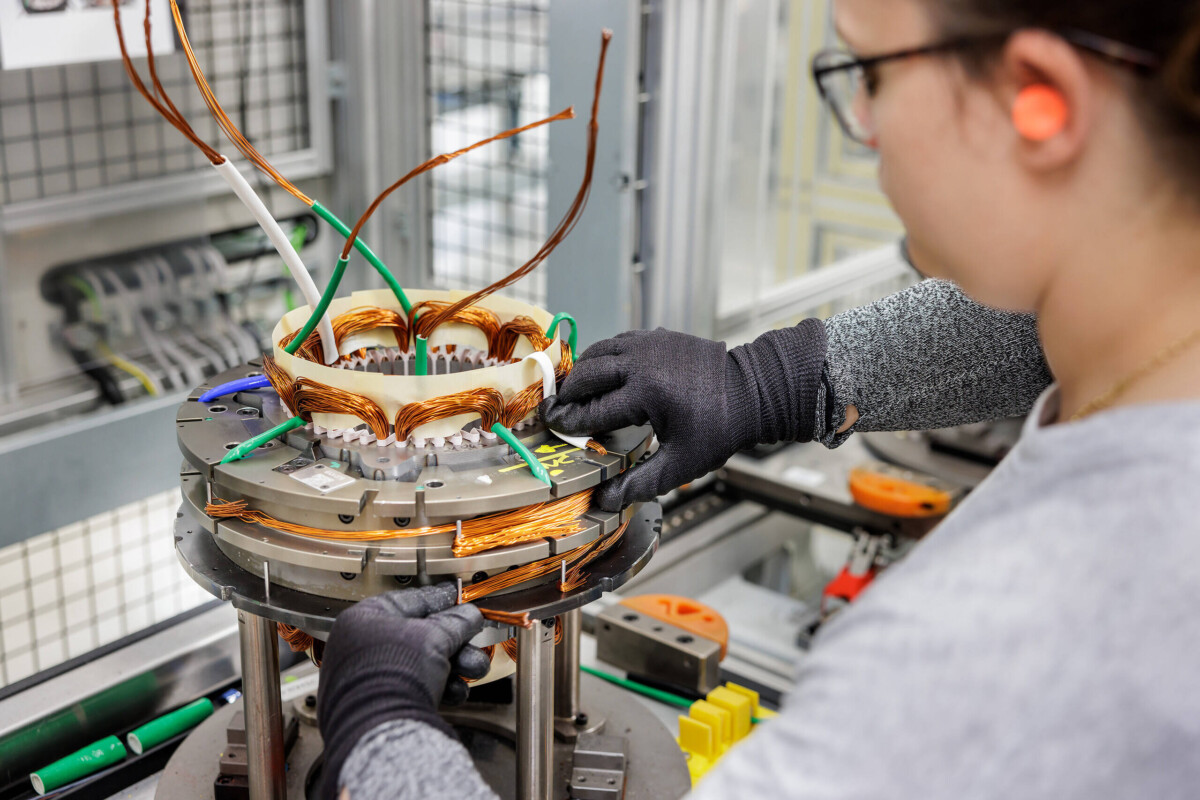

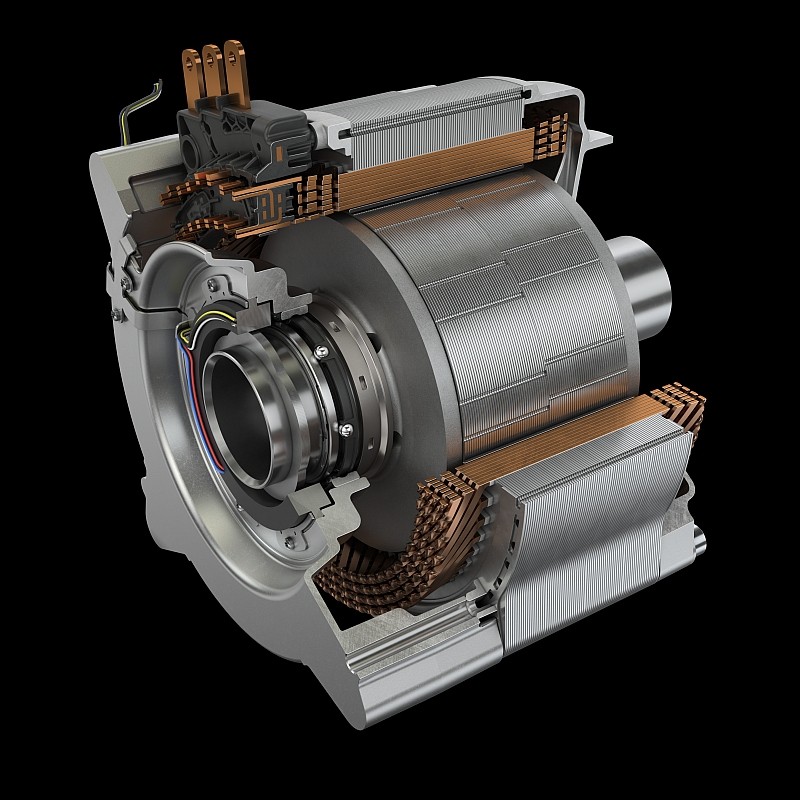

In any case, an accumulator is never thrown away as is, which would obviously be ecological nonsense. But what about the engines? In some cases, these are recycled. To do this, they are simply dismantled and certain elements such as copper are recovered. But this is not always possible. Thus, it is necessary to continuously produce new ones in order to equip cars leaving the factory or to replace a defective unit.

Obviously, and as for lithium-ion batteries, this requires rare materials or whose extraction and processing is polluting, such as copper or aluminum. Fortunately, scientists are currently looking for solutions to reduce the demand for new engines. How ? Quite simply by reusing those that already exist. This is precisely the aim of REASSERT project.

The latter is currently led by the Fraunhofer Institute, located in Germany. The goal is in fact very simple, since it consists of establishing a complete revaluation process used electric car engines. The objective is to avoid outright recycling as much as possible in favor of reuse in order to increase the lifespan of this essential element.

A complete process

It works more or less like electric car batteries. If an engine is not too damaged, for example if the car was scrapped following a small impact, it can be reused. It will be restored with the help of parts from blocks that have been dismantled, which helps improve the circular economy. The use of new parts is then considerably reduced.

This also reduces demand for materials such as neodymium, of which China has a virtual monopoly in the world. However, we know that the European Union wishes to reduce its dependence on the Middle Kingdom over the coming decades.

Thus, Julian Große Erdmann, one of the scientists in charge of the project, explains that “ we want to establish a closed-loop system in which valuable resources are reused in order to eliminate dependence on imports of raw materials“.

The process is simplified thanks to a tool using artificial intelligence, designed as part of this project. The latter is then responsible for helping to choose the preservation and valorization strategy the most suitable depending on the engine. The device is able to judge whether a block can be repaired or whether another needs to be dismantled. But the German institute wants to go even further.

Ultimately, he hopes design an engine prototype adapted to the circular economy and able to be better revalued when it reaches the end of its life. This solution could also reduce the price of electric cars, which would use reconditioned blocks that are less expensive to produce than new ones. This would also be useful for developing the practice of retrofitting, which consists of transforming a thermal car into an electric one.