Lightyear, the famous start-up and its solar car, will use an electric motor with exceptional efficiency, directly integrated into the four wheels of the vehicle.

The performance of electric car motors is one of the arguments put forward by engineers to assert their superiority over internal combustion engines. Usually, electric motors have an efficiency close to 95% while thermal motors run more below the 50% mark. In other words, on a combustion engine, half of the gasoline is used to move the car forward, the rest being lost in the form of heat.

97% efficiency for a motor integrated into the wheels

Lightyear, the Dutch company to which we owe the Lightyear 0 solar car sold for 300,000 euros, announces that it has entered into a partnership with Elaphe, the Slovenian specialist in electric motors. Together, they succeeded in developing an electric motor with an exceptional efficiency of 97%.

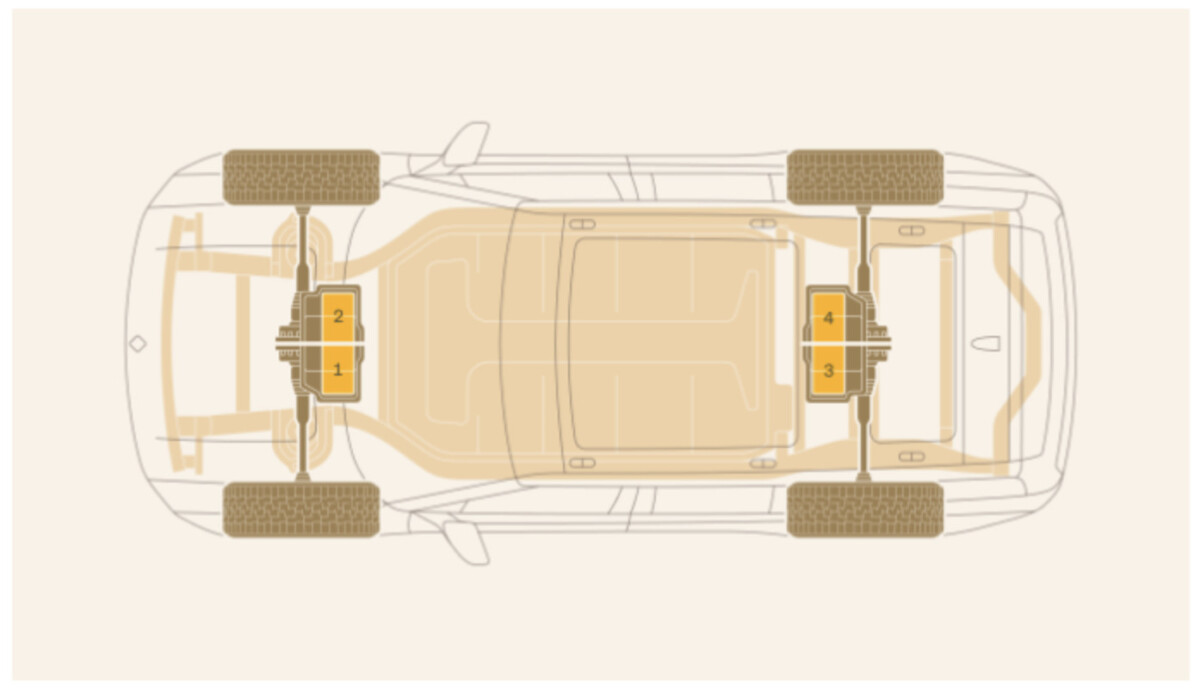

To achieve this result, several elements differentiate this engine from its competitors. The first thing is thatit is a motor directly integrated in the wheel. This makes it possible to dispense with the conventional transmission system (and in particular gearbox and differential), by being in direct contact with the wheel. In the case of the Lightyear 0, there are four motors: one for each wheel. This explains, in part, the excellent consumption of the car at high speed.

The other manufacturers opt for motors placed on the axles, with a motor for four wheels or a motor for two wheels. There are sometimes three motors (as on the Tesla Model S Plaid), but these always rest on the axles. The two rear wheels then each have their own engine, but always with a transmission system that weakens performance. The advantage: improved road holding.

The advantage of having one motor per wheel

Some manufacturers go even further and offer four motors, one per wheel. This is the case of Rivian with its R1Ts and R1S or even of Mercedes with its future EQG. But as in the case of three-engine cars and unlike Lightyear, the four engines are not integrated into the wheels but into the chassis, with one gearbox (single speed) per engine. The advantage here: the possibility of making a U-turn on the spotlike a tank.

The motors integrated into the wheels do not only have advantages, however. They have the disadvantage of costing more than a more traditional engine. In addition, they are not suspended with the rest of the chassis and must therefore endure the various shocks that the wheels take. Finally, their greatest disadvantage and their limited power due to the absence of transmission which forces the motor not to turn very fast. We see it on the Lightyear 0 and its 1,720 Nm of torque for only… 172 hp of power!

Either way, it seems in-wheel motors are a big hit with solar car makers. Indeed, after Lighyear, it is the turn of Aptera with its three-wheeled solar car to announce a partnership with Elaphe for the supply of electric motors integrated into the wheels. The Aptera will be available in several versions, with two front-wheel drive, or with three-wheel drive.

To follow us, we invite you to download our Android and iOS application. You can read our articles, files, and watch our latest YouTube videos.