There are only two copies worldwide of Daisy, one in Austin, Texas and the other in Breda, the Netherlands. Each can process up to 200 smartphones per hour, or more than a million over a year. It sounds huge, but to put it all into perspective, know that Apple in 2022 brought no less than 225 million iPhones to market…

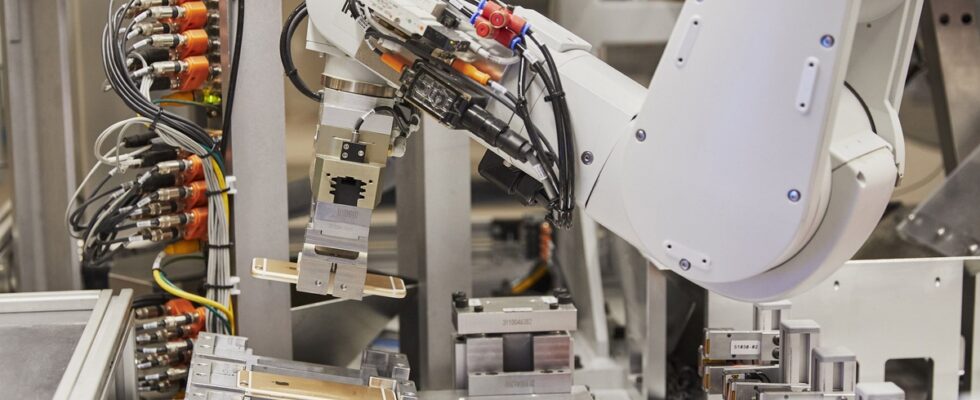

Each smartphone is subject to very precise processing. It starts with identifying the model (from iPhone 5 to iPhone 12) followed by separating the screen from the rest of the components. The device is then opened and Daisy can remove her battery. This operation is delicate, because the battery of the iPhone is maintained by powerful glue. To overcome it, you have to send icy air over it for several seconds. The battery can thus be recovered without damage. Then, the various screws of the device are removed in order to be able to separate and recover each component of the phone. These then fall on a conveyor belt which leads to the exit, where a human takes over to distribute all this waste in large dedicated bins. And that’s how every 18 seconds a new iPhone is completely disassembled.

This therefore results in large bins where screens, batteries, front and rear cameras, connectors, etc. are packaged separately. They will then be sent to the four corners of the world, to different partners, in order to be recycled, in one way or another, and reinjected into the market.

A long tradition of disassembling robots

Daisy is actually the most evolved version of a series of robots developed since 2013 by Apple. The very first, Liam 1.0, was responsible for disassembling the iPhone 5s, an operation that took him no less than 12 minutes at the time. In 2015, its evolution Liam 2.0 was dedicated to the iPhone 6 only. Even if this time the operation only took a few seconds, this solution was still far too limited. Today, Daisy is compatible with around twenty models, but can above all be updated and thus become compatible with more recent generations of iPhone.

In addition to Daisy, Apple currently operates other robots that help recycle iPhones. This is the case in the United States with Taz, a crusher responsible for separating magnets from audio modules in order to recover rare earths, and in China with Dave, capable of recovering these same elements present in the vibrator of the ‘iPhone.

Note that in its program to achieve carbon neutrality for all of its production by 2030, Apple wants to be able to use recycled and renewable materials almost systematically. The American manufacturer notably aims to use 100% cobalt and rare earths in the production of its entire range of products.

Remember for all practical purposes that to limit the impact on the environment, recycling is an important operation, even necessary, but it is even more important to limit the use of raw materials keeping your smartphone as long as possible by favoring the model change repair.