The area around Dunkirk is one of the largest industrial crossroads in Europe where a fifth of French industrial emissions are concentrated there (AFP/Archives/Denis CHARLET)

A small factory within the factory: from 2025, in the north of France, the lime factory of the Belgian group Lhoist should be equipped with new towers and pipelines. Not to produce more CO2, but to capture it and contribute to decarbonizing this highest-emitting industrial region in the country.

The area around Dunkirk is one of the largest industrial hubs in Europe, ideally located on the edge of the North Sea. Steel, cement and fertilizers are produced here in factories that emit millions of tonnes of greenhouse gases. No less than a fifth of French industrial emissions are concentrated there.

“We have a production capacity of 700,000 tonnes of lime per year, so we emit roughly the equivalent in CO2,” explains Yves Boraccino, director of the immaculate Lhoist factory in Réty (Pas-de-Calais), almost every wall of which is covered with limestone dust from a neighboring quarry.

Like all European industry, the factory of the world leader in industrial lime, essential for the steel industry and papermaking, wants to capture the CO2 generated in chemical processes before it spreads into the atmosphere.

Carbon capture and storage is one of the solutions that manufacturers will promote at COP28 at the end of the year to achieve the objectives of the Paris climate agreement, but as the Dunkirk area illustrates, it It will still be years before these technologies reach an industrial scale.

To achieve this, Lhoist called on another giant, Air Liquide, a specialist in oxygen and industrial gases.

– CO2 terminal –

Conveyed to the Réty factory in an uninterrupted ballet of trucks, the mounds of limestone are heated for 24 hours in cylindrical kilns around fifty meters high, at around 1,000 degrees to produce lime… and emit two thirds of the CO2 produced by the site, the remaining third coming from fuel.

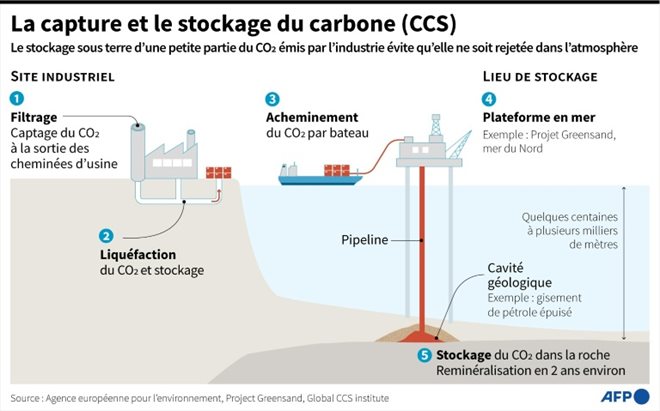

CO2 capture and storage (AFP/Valentin RAKOVSKY, Paz PIZARRO, Anibal MAIZ CACERES)

The ovens operate “mainly on natural gas”, and today with “30% biomass (…) wood pellets”, specifies Jacques Chanteclair, general manager of the group for Southern Europe.

The CO2 that escapes when heating limestone is considered inevitable by the industrialist, hence this capture project.

The CryoCap unit developed by Air Liquide, a pilot of which is being tested on the Port-Jérôme industrial site (Seine-Maritime), will be connected to the factory chimney outlet. “We are going to connect via a large pipe to the exhaust pipe of the Lhoist factory, we are going to recover these fumes,” describes Nicolas Droin, general manager of Air Liquide France Industrie.

These fumes will be filtered via chemical and physical processes. “Then, we will, via a cryogenics system, lower the temperature of this gas which has been previously purified,” he explains.

At -50°C, the CO2 will transform into a liquid and the other components will remain in the gaseous state, allowing the CO2 to be recovered.

Freed from other impurities, this CO2 will be sent by pipeline to a special terminal in Dunkirk, which is to be put into service in 2028, to initially accommodate some 1.5 million tonnes of CO2.

– “Industrial Revolution” –

Because the “Chaux et Dolomies du Boulonnais” factory, which is celebrating its 60th anniversary, is not the only one undergoing its revolution. A cement plant from the Eqiom group, a few kilometers from the Lhoist site, is in the running to capture its carbon and ship it to Dunkirk.

“From there, it can be transported by boat to geological storage sites in the North Sea,” says Mr Boraccino.

In addition to Lhoist and Qiom, this project valued at 530 million euros, including a large part of European funds, could handle up to 4 million tonnes of CO2 per year in the medium term, according to Air Liquide and its partner Dunkerque LNG. .

This would allow steelmaker ArcelorMittal, which is testing another carbon capture process, to connect next.

The entire region is transforming around the low-carbon “industrial revolution”, as the president of the Dunkirk urban community Patrice Vergriete says, which is striving to attract electrification industries, such as several battery factories.

This dynamic affects the whole world: the number of carbon capture projects in pipes “almost tripled in 2021 and has almost doubled again since,” underlines the International Energy Agency (IEA).

But the agency recommends reducing CO2 emissions at the base, warning against the use of these “expensive” and still “unproven on a large scale” capture technologies.

The IEA reports that only 5% of projects announced worldwide have at this stage obtained the green light for financing.

For the Lhoist factory in Réty, the verdict is close, according to Mr. Chanteclair: “The final investment decision is planned for the end of 2024.”

© 2023 AFP

Did you like this article ? Share it with your friends using the buttons below.