The evidence is increasing: The serious defect in Alaska Airlines’ Boeing 737 MAX is not an isolated case. Aviation expert Gerhard Wissel suspects a structural problem in production and quality assurance. The US aircraft manufacturer does not have to fear series of cancellations.

Since two Boeing 737 Max jets crashed five years ago and 346 people died, the US aircraft manufacturer has not been able to get out of the crisis. Last week’s incident further damaged the company’s already tarnished reputation.

After a part of the fuselage broke out of an Alaska Airlines jet in the middle of a flight last week, aviation expert Gerhard Wissel is certain: “It was pure luck that the passengers escaped with a shock,” he said in an interview with ntv.de . The plane was currently climbing, the air pressure was not particularly high, the seat in question was free and the passengers were strapped in. “Fifteen minutes later, if the passengers had already unbuckled themselves and the cabin crew had started the service, the outcome would have been much more dramatic.”

In response, the US aviation authority FAA ordered a temporary flight ban for the 170 aircraft worldwide different airlines and prompt inspections. A decision that, according to Wissel, is one hundred percent right for them Airlines but it is a losing proposition. You now have to react during ongoing operations. “Cancellation or rescheduling will result in lost revenue, which will be billed to Boeing.”

Does Boeing have a tight enough grip on its own organization?

The inspections now need to find out: Is the origin of the problem in the design, production or maintenance? There are now increasing indications of a more far-reaching problem: the serious shortage of Alaska Airlines’ Boeing 737 MAX may not be an isolated case. The airline said technicians had also discovered loose parts on other aircraft of the affected type. The plane’s second major user, United Airlines, also said it had found loose screws during inspections.

“Since the problem affects several aircraft, a maintenance problem can be ruled out,” says Wissel. The US aviation safety authority NTSB also said it was unclear whether the part that broke off during the flight was properly installed.

Hull parts are usually riveted. This is much more stable. Other parts such as doors or emergency exits are simply screwed on. Since a maintenance problem is unlikely, the question now needs to be clarified: Can the incident be traced back to a design-related problem? It would have had different screws or a different type of assembly must be used for the fuselage part? Or was there some sloppiness during production? Have the screws not been tightened enough that they have become loose due to vibration?

“I assume that the incident is a production-related problem,” says Wissel. In this case, the company has to ask itself the question: Does Boeing have enough control over its own organization to deliver an aircraft that is truly airworthy and 100 percent safe? The aviation expert assumes that airlines will drastically shorten the maintenance intervals for this particular element on their own. In his opinion, Boeing also has to ask itself another question: Does a fundamental change need to be made to the aircraft?

Detected defects suggest a fleet problem

CEO Dave Calhoun has now admitted that the aircraft manufacturer made a mistake and promised to clarify the matter. “The way we’re going to approach this is, first of all, admitting our mistake,” Calhoun said. He also promised 100 percent transparency, according to a published excerpt of his speech. Boeing will work with NTSB accident investigators to determine the cause of the incident.

Some analysts had initially expected the fallout for Boeing to be limited, as long as it was a single technical blip. But the deficiencies in other planes discovered by the airlines now suggest a fleet problem.

At Boeing, the accident follows a series of development and production errors. Again and again it’s the “Max” – the latest edition of the 737 medium-haul jet, whose basic design dates back to the 1960s. Medium-haul jets are the most popular aircraft types – and the “Max” is the most important source of revenue for Boeing. With further development, the US group responded to the success of the Airbus A320neo medium-haul jet family.

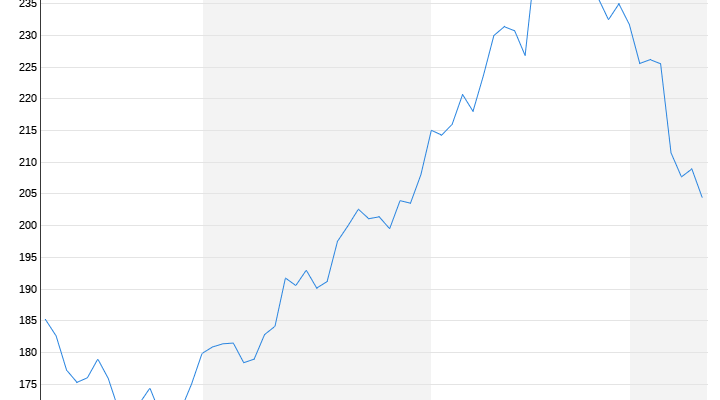

Its European competitor Airbus has long been outpacing Boeing. Boeing has been inferior to its rival for five years now. Boeing delivered 528 aircraft last year, compared to 480 the previous year. According to insiders, Airbus exceeded its delivery target of 720 aircraft with 735 jets.

Way out of the crisis of trust

Boeing has repeatedly been accused of sacrificing quality and safety in order to achieve higher returns. “In principle, this is difficult to prove. However, the current incidents and also the incidents in the past in production and quality assurance indicate a structural problem at Boeing,” says Wissel.

However, it is not to be expected that customers will now cancel their orders in droves. Ultimately, despite all the problems, the airlines have no choice but to continue to rely on Boeing. According to Wissel, the large airlines in particular have no interest in becoming dependent on just one manufacturer.

Since neither the Russians nor the Chinese will bring any real production-ready alternatives onto the market within the next 10-20 years, only Boeing and Airbus remain as manufacturers of these aircraft. “If one provider were to go away, a monopoly would arise, which would have a detrimental effect on prices, availability and also innovations or aircraft developments,” says Wissel.

The group can only get out of this crisis of trust if an independent audit is initiated that examines the entire process. Wissel urgently advises the group to disclose its vulnerabilities as quickly as possible and to prove that they are being worked on.