It’s the sauce, sweet or savory, that you use in Asian restaurants almost without realizing it.

Kikkoman Foods, the Japanese agri-food giant, has just digitally modeled its soy sauce production plant in 3 dimensions, using Matterport’s capture service as a service provider. The idea? Create a digital twin of the Imperial Soy Sauce Brewery, which supplies the famous Goyogura.

This factory was built in 1939 to serve as a brewery dedicated to soy sauce. It was initially intended to supply the famous sauce to the Imperial Household, which it continues to do, among other clients. The factory uses traditional methods of producing soy sauce on a large scale.

Only three hours of work

The factory was scanned using a capture service provided by Matterport, which used a Matterport Pro3 scanner equipped with LiDAR and RGB sensors to scan spaces and distances.

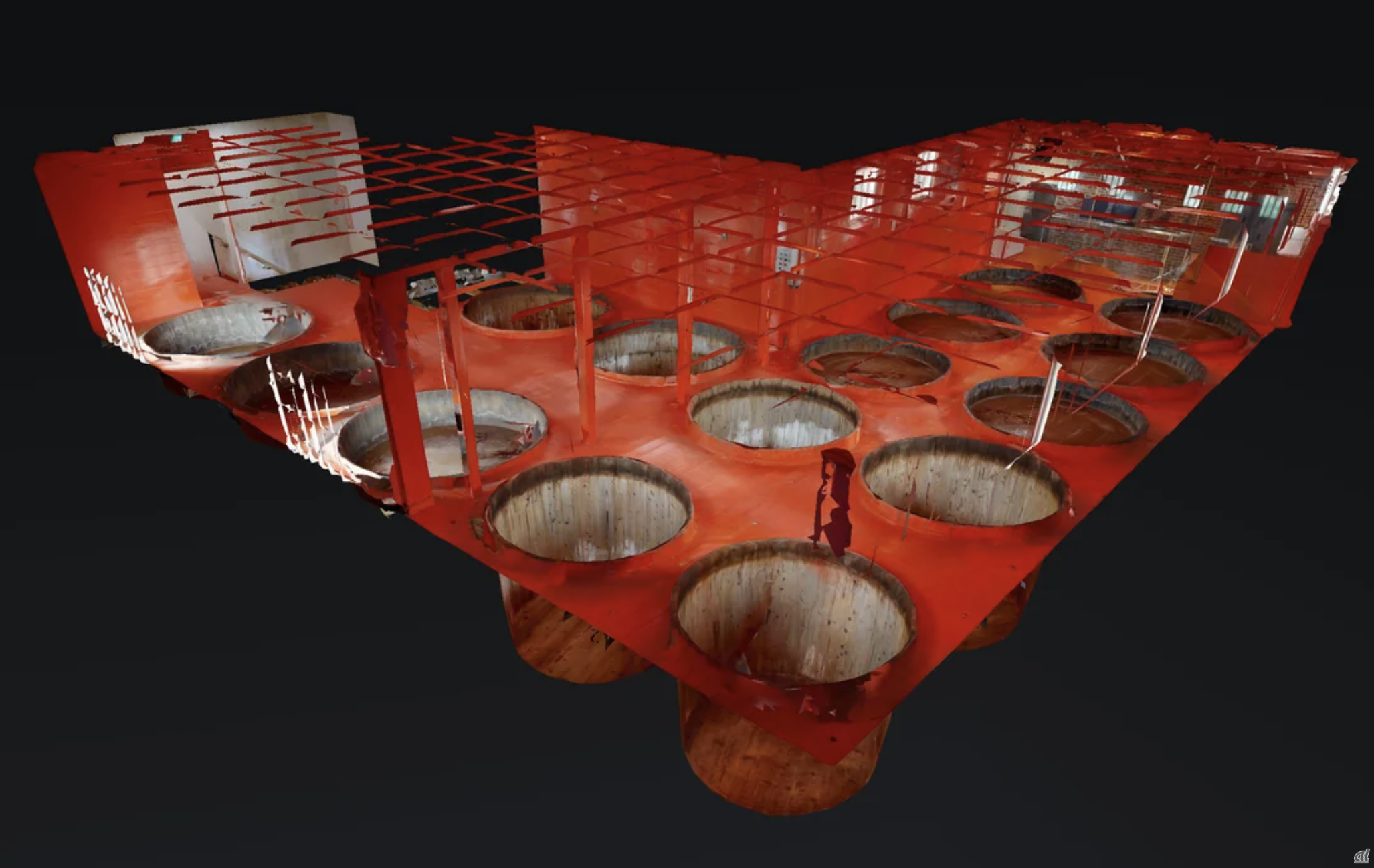

It took about three hours to photograph the exterior, interior of the brewery and even highly detailed areas such as those between the “brewing vats” used to mix and prepare the ingredients needed to make soy sauce . The photographed data is then combined fully automatically in Materport’s cloud computing service and can be viewed as a digital twin on a web browser.

Virtual representation of the soy sauce brewery. Marterport

The company’s digital twin is intuitive and can be easily used by people without specialist knowledge, assures the service provider. For example, the digital twin’s “measurement mode” can measure the facility’s interior, exterior, and equipment, and Kikkoman can add and edit memos, documents, and videos.

Pedagogy and maintenance

Kikkoman says building this digital twin allows for visualization of the picking room and warehouse interior, which normally cannot be seen together at the physical site. Enough to offer a virtual tour to the general public. In addition, as texts, documents and videos can be integrated into the digital twin, it will also be used as educational content to disseminate the traditions of soy sauce production and food culture to the public.

Tag function to paste text and characters into space. Marterport.

In addition, Materport’s digital twin, which reproduces every detail, can also be used for maintenance and facility management. The digital twin can be shared with relevant departments for repairs and maintenance. By measuring the dimensions of the space on the digital twin and writing instructions in the digital space, communication can be accelerated and travel costs can be reduced.

The company also claims that virtual access to the factory also reduces hygiene risks and streamlines factory management by limiting the time and effort required for the removal of sanitary garments and the associated disinfection process. upon entering the factory.

Source: “ZDNet Japan”