If the electric Peugeot E-3008 will ultimately benefit from batteries produced in France, we will have to wait until 2025 for the manufacturing plant to be ready. The first examples of the electric car will therefore have to use Chinese BYD cells… but they turn out to be surprisingly less efficient than future French cells. We will explain everything to you.

THE Peugeot E-3008 electric and the Renault 5 E-Tech have one thing in common: their desire to have a maximum of elements made in France. The electric Peugeot is thus manufactured Sochauxin the brand’s historic factory, and its batteries are assembled in parallel with the production line.

What about the cells that make up these batteries? If they will eventually produced in the ACC gigafactory in Douvrinin Pas-de-Calais (62)… they must for the moment be purchased to Chinese BYDone of the world leaders in batteries, and Tesla’s biggest competitor, pending the opening of the French factory.

In parallel with the tests of the electric 3008, we were able to speak with Christophe Patois, its engineering director. This is the opportunity to make plenty of discoveries.

A new platform

The E-3008 is an important car for Peugeot (and its Stellantis group in general) for several reasons. On the one hand because the brand hopes to sell like hot cakes, but also because the SUV inaugurates a new platform, called STLA Medium.

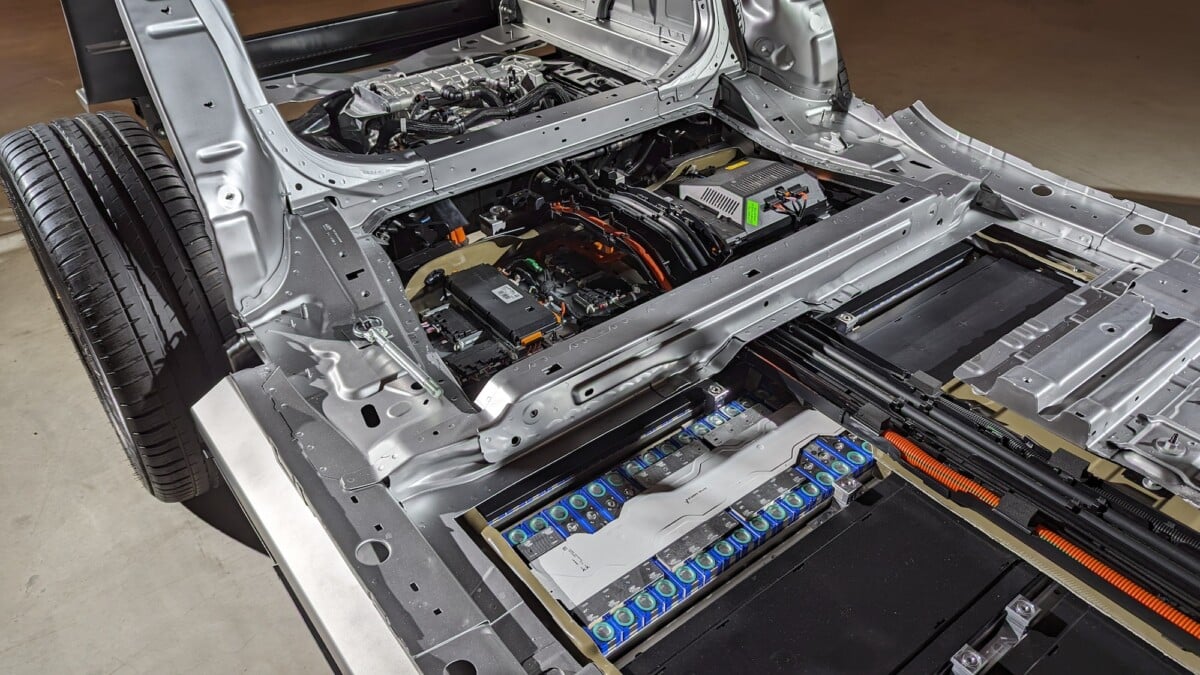

A new generation multi-energy platform (understand: compatible with thermal, hybrid and 100% electric engines), capable of accommodating batteries ranging up to 98 kWh of net capacity (a priori 103 kWh gross). “Putting 98 kWh in a wheelbase (the distance between the front and rear wheels, Editor’s note) so short was an achievement”Christophe Patois explains to us.

“To get there, we had to push the four corners and scrape every inch possible”, he adds, showing us the beveled rear ends to allow the wheels to pass through. The fact remains that this 98 kWh version… we will not be entitled to it straight away, since we will have to wait February 2025 at the earliest.

A range in several stages

When it is launched in spring 2024, the electric 3008 will only be entitled to the “standard” pack of 73 kWh net (approximately 77 kWh gross). “We had to make a choice”justifies Gaëtan Dumoulin, the project manager, before specifying: “we couldn’t develop all the versions at once, and we focused on the version that will be most widely distributed”.

This first version, as a reminder, combines a front engine (making this E-3008 a front-wheel drive) 210 hp to this famous 73 kWh capacity battery, all giving a range of 527 km on the WLTP cycle. Recharging level, you have to count on a 20 to 80% in 30 minutesvia a maximum power of 160 kW.

A version which will therefore be joined in a year by the 98 kWh capacity battery, therefore, targeting a range of 700 km. The front engine will be taken over, but pushed to 230 hp thanks to the superior discharge power of the battery. Recharging? Promised to 30 minutes also, thanks to work on the charging curve – the battery being larger, the average power can be higher.

And it doesn’t stop there, since a third variant will arrive at that time. It will use the 73 kWh battery, but will add a second motor at the rear, enough to make this 3008 electric all-wheel drive.

The power logically jumps to 320 hpenough to improve performance: 0 to 100 km/h goes from 8.8 s to 6.4 sec and the acceleration from 80 km/h to 120 km/h melts, going from 5.6 s to 3.9 s.

Asked about this rather late date of February 2025, Christophe Patois gives us the explanation: “These two variants will only have ACC cells, and we must therefore wait for the full opening of the ACC gigafactory in Douvrin”. The opportunity to open the discussion on the differences between the BYD cells, which will equip the 3008 upon its release, and the ACCs to come.

BYD vs ACC: the winner will surprise you

A little context

Let’s start with a quick reminder. BYD, in addition to competing with Tesla to become the world’s number one manufacturer of electric cars, turns out to be one of the world’s leading battery cell suppliers via its subsidiary FinDreams.

FinDreams is also known for its in-house battery, called Blade, which equips the brand’s cars… but also the Tesla Model Y Propulsion manufactured in Berlin. A remarkable LFP (lithium – iron – phosphate) type battery, capable of recharging very quickly (10-80% in 20 minutes on the Model Y), almost impossible to ignite and with an extended lifespan, all while remaining relatively inexpensive.

Be careful though: this Blade is not in the program of the E-3008, who prefers a so-called NMC (nickel – manganese – cobalt) battery. A more expensive technology, but also with better energy density. Which is not necessarily a bad thing: this electric 3008 is already very heavy, and an LFP would have made things even worse.

The heart of the matter

In detail, the BYD battery of the E-3008 is divided into 12 modulesall heavy 520 kg. Chemistry ? 60% nickel, 20% manganese and 20% cobalt (we are talking about an NMC 6:2:2 battery).

This is where things get tricky, since the upcoming ACC battery turns out to be… more efficient than BYD’s! What to offer better performance? ” No way “Gaëtan Demoulin and Christophe Patois answer me, “we wanted to keep the same figures for both technologies in order to maintain readability in the range”. Understandable.

In fact, this ACC battery only needs 11 modules to reach 527 km of autonomy. No gain in the cabin or trunk, but 30 kg saved (or “only” 490 kg in total). As for the charging times, even if no figures have been specified, they should be similar – always with this idea of transparency for the customer.

The charging power will therefore remain at 160 kW, but the discharge power (what the battery sends to the motors) should be greater than the BYD battery, thus making it possible to reach the 320 hp of the 4×4 version.

The secret ? A different chemistry : here we move to a mix of 80% nickel / 10% manganese / 10% cobalt. So we have, if you follow closely, an 8:1:1 NMC battery.

A chemistry and number of cells shared with the 98 kWh pack, which will simply be thicker (downward, no change in edge space) 15mm. It will be necessary a priori count 590 kg for this pack (+100 kg vs the 73 kWh pack), which will not help the weight of the E-3008.

Let’s end with some good news: repairability has been taken into account, since each module can be changed individually – it would take around 1h30 in the workshop. A good thing, because not everyone can say the same.

What to conclude? How happy we are that the cells manufactured in France are beneficial both for jobs… and for the electric cars that are equipped with them. And this is only the beginning, since Gigafactory projects are growing like mushrooms in France, and more particularly in the north.

A regret ? Come on, it’s a shame though recharge times are not at the best level for this brand new STLA Medium platform.

Partly the fault of the choice of a 400 volt architecture (going to 800 volts would allow recharging in less than 20 minutes, like at Hyundai or Kia), even if Stellantis assures that this platform is ” flexible “ And “evolutionary” over time ; what can we hope for in the years to come?

Want to find the best Frandroid articles on Google News? You can follow Frandroid on Google News in one click.