Wednesday February 10, 2021

Outperformed competition

Toyota defies chip crisis thanks to customer care

The world's largest car manufacturer Toyota is not feeling the supply bottlenecks for chips. The reason for this are long-term close ties to manufacturers. As a result, the Japanese report brilliant numbers and want to increase production – while the competition has to slow down the production lines.

Toyota stands out from the competition in the pandemic and proves to be more robust in the chip crisis. While other automakers – including the two local rivals Nissan and Honda – have to cut back their production because of the rampant global shortage in semiconductors, the Japanese flagship company has announced that it will even increase its output. The group has a supply of chips for up to four months and currently does not expect production to be impaired.

When asked why the impact at Toyota was limited, Chief Financial Officer Kenta Kon replied that Toyota kept its suppliers informed of its short and long-term production plans. "In the short term, we do not see any decline in production volume due to the shortage of chips, but we do see the risks of a shortage of chips." There are voices that assume there will be a shortage of semiconductors by summer. But it may not take that long.

In contrast to its Western competitors, Toyota traditionally maintains close relationships with suppliers at various levels and has long been financially involved in many. In this network, called keiretsu in Japanese, close coordination is possible. The lack of direct agreements with semiconductor manufacturers is seen as one of the reasons for the chip bottleneck at many other manufacturers. Volkswagen therefore wants to enter into direct supply relationships in the future. So far, the Wolfsburg-based company has been purchasing parts from suppliers such as Bosch and Continental, which in turn are supplied by semiconductor manufacturers.

Car manufacturers around the globe are affected by the shortage of microcontrollers used in engine management and driver assistance systems. VW and Daimler also suffer from it. In order to discuss the consequences of the bottleneck, representatives of the auto and electronics sector and the French state want to meet for a crisis meeting on Wednesday.

Toyota also stands out in terms of profit: The operating result climbed in the period from October to December by more than half to around 7.8 billion euros (988 billion yen). That was significantly more than analysts had expected. For the fiscal year ending in March, management now expects an operating profit of two trillion yen, far more than management had previously forecast.

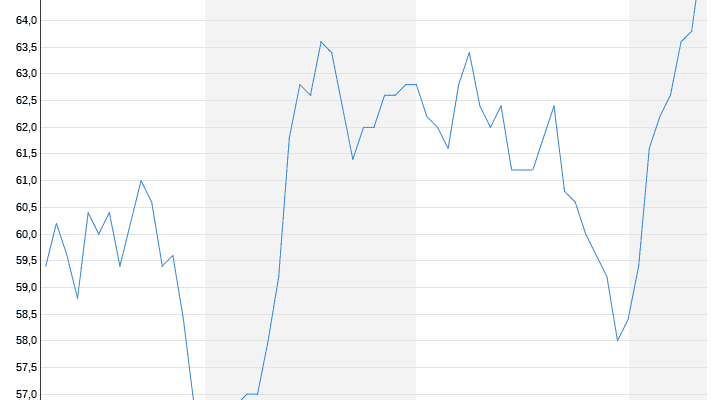

Toyota shares closed 1.7 percent higher after previously climbing to their highest level since July 2015. The fact that Toyota is not as badly affected by the chip shortage is an encouraging sign, said Hideyuki Suzuki of SBI Securities.

Toyota expects sales of 9.73 million vehicles this year, 3.3 percent more than the group had previously forecast, but less than last year's 10.46 million. The manufacturer of cars such as the SUV RAV4 and the hybrid model Prius came through the Corona crisis better thanks to the Asian market – mainly due to its strength in China – and for the first time in five years it ousted its German rival Volkswagen from the top of the world market. The group had only raised its forecast for operating profit to 1.3 trillion yen in November.

. (tagsToTranslate) economy (t) auto industry (t) automaker (t) Japanese automaker (t) Toyota (t) quarterly figures