Sunday, March 7th, 2021

Overcrowded on the oceans?

Freighters lose 3000 containers in 80 days

By Diana Dittmer

Shipping companies are happy about the order boom in the second lockdown. Your container business is buzzing. The ships from Asia are full to the brim, boxes in China are in short supply, which is driving up prices. The fact that accidents are increasing is bad news. Is there a connection?

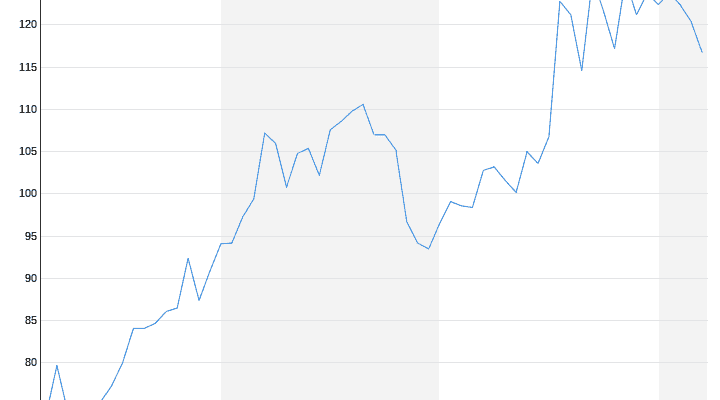

The supply chain from Asia to Europe or the USA remains tense: there are too few cargo ships and containers to meet the high demand for consumer goods from China. In the first half of the pandemic in 2020, there was initially absolute slack, in the second lockdown, the shipping companies' business is now buzzing. The result: there is a global jam and the ports are overcrowded. Especially those who shop in China have to be prepared for long waiting times. Everything that can swim is on the water, say insiders. In view of the high demand, freight prices have risen tenfold, as entrepreneurs ntv.de confirm. The ships are so full that more containers apparently go overboard in heavy seas.

If hundreds of them suddenly float in the ocean, as was recently seen in the Pacific off Japan, it is not only dangerous for shipping. The question also arises how this can happen. Even more so when the situation is so tense and incidents of this kind pile up, as was the case recently. According to official information, six accidents of this type have been reported in the past few months. More than 3000 containers were lost. The number of unreported cases of wrecked container ships is considered to be high.

The worst incident occurred in November on the Japanese freighter One Apus, when 1,800 containers fell into the sea in 16-meter waves. In mid-January, the Maersk Essen lost 750 of its 13,000 containers on board in heavy seas. Her sister ship Eindhoven two weeks ago another 260. Both ships of the Maersk shipping company were fully loaded on the voyage from Xiamen in China to Los Angeles. Videos from the One Apus and the Maersk Essen show the damage that boxes torn out of their anchorages cause on the ships. After the accident in Mexico, Essen had to make a stopover.

High activity on the oceans

The crews were not injured. Nevertheless, the incidents are worrying the shipping industry. Analysts and insurers have also pricked up their ears. It happens again and again that the freighters lose cargo in bad weather conditions. But this winter the losses are significantly higher than usual. According to the Washington-based trading company World Shipping Council, the approximately 5,500 cargo ships that sail the world's oceans reported an average of 1,320 containers overboard per year between 2008 and 2019. That's less than half.

Are they "unfortunate individual cases" or is there a structural problem behind them, container analyst Lars Jensen from Denmark-based SeaIntelligence Consulting asks openly. He himself does not rule out a connection: "The higher you stack the boxes on deck, the greater the forces they are exposed to when the ship moves in the waves. That could be a factor, especially since the recent boom in demand led to it has that all ships are loaded to the stop ", quoted the" Wall Street Journal "Jensen.

The order boom after the sales slump in the first lockdown gave the shipping companies an unexpected boom. Because there is a lack of ship and container capacity for the goods, delivery bottlenecks arise. For some goods, such as bicycles, sports equipment, furniture or television sets, there are sometimes waiting times of three to four months for consumers, as Nils Haupt from Hapag-Lloyd ntv.de explains. All ships of the shipping company are in use, in and in front of the ports there is a lot of activity. "For example, around 40 ships are currently waiting in front of the port of Los Angeles / Long Beach that cannot dock due to the port's overload," said Haupt.

Because there are currently not enough empty containers, the return of empty containers from Europe or the USA to the Far East is now a priority, says Haupt. On some routes, "sometimes even full containers have to be left in the USA or Europe". He is unable to say when the situation will ease, because many orders come at short notice. By the end of the first quarter, the order books are full: "At the moment, we cannot offer our customers any free capacity on our ships in many traffic areas at short notice."

150 million containers per year

Has that caused freight traffic across the oceans to become more unsafe? In the past few months, extraordinary weather conditions have also contributed to the delays, Haupt continues. Severe storms would also have caused significant incidents. On the ships and their container loads, some of which are stacked up to 10 layers of containers, extreme forces would act on the ship and the container superstructure in such weather situations, he explains.

In professional circles, the phenomenon is known as "parametric rolling". It causes problems for container ships when waves do not hit the front from the front, but diagonally from the side. They get rolling. Either way, however, it is a marginal problem for Haupt: "If 3,000 of a total of 150 million containers that are transported per year are lost, the percentage is negligible and, unfortunately, can hardly be avoided in extreme weather." He does not see any failures or errors in loading and stowing the containers on the ships. The number of containers and the weight on the steel giant is standardized. Stowage planners and additional software sorted the container boxes in such a way that they were safe. In addition, the boxes would be locked together, lashed with lashing bars and then connected to the ship's structure again.

Maersk announced "a detailed cargo assessment" after the Essen accident: "The US Coast Guard, the flag state and the relevant authorities have been notified. We view this as a very serious situation that will be investigated promptly and thoroughly." Maersk is based in Copenhagen, the freighter sailed under the Danish flag.

Expert: Artificial intelligence should improve processes

Everyone agrees that there is room for improvement in the logistics of cargo shipping. Hapag-Lloyd boss Rolf Habben Jansen recently told journalists that he is aware "that customers are worried about disruptions and high spot freight rates." He will try to dispel these concerns "through more transparency" in the contract tariffs. "It is in our best interest that everyone continues to containerize as many goods as possible at competitive costs."

Alexander Nowroth from Lebenswerk Consulting advises companies on reducing sea freight costs and securing capacities through logistical solutions: He sees a need for optimization in communication between seaports and shipping companies and advocates more AI in the handling of ships. This could, for example, ensure that overcrowded ports are only approached when cargo can be unloaded promptly. The fact that the situation is easing depends primarily on two factors: "The shipping companies must use all capacities, even when demand cools, so that a yo-yo effect does not occur in freight rates again. In the past, there were Departures by 'blank sailings' are often canceled prematurely, "says the former Maersk man. That reduced costs, but severely restricted flexibility. "Second, shipping companies must make unreliability in their own fleet more punishable," continues Nowroth. The ports should not be blamed alone.

The fact that container shipping and its insurers are currently investigating the frequency of accidents in order to determine whether there is a connection between the incidents cannot initially dampen the joy of shipowners at the unexpected boom. Hapag-Lloyd expects a record profit of 1.25 billion euros for the first quarter – nine times more than in the same quarter of 2020.

.