The 3D printer market is constantly evolving. In addition to improved technology and falling prices, the increasingly larger installation space is particularly exciting. In the past, if you wanted to print large objects, you had to print them in several individual parts and then glue them together. Much more convenient are printers that also allow large printouts in one piece. Examples of such large-capacity printers are the X5SA (test report), X5 SA Pro (test report), Sapphire Plus (test report) or ET5 Pro (test report) models. But when is it worth buying a large printer?

Resin printer

Resin printers offer the smallest print size. The costs for the devices and the resin have fallen sharply, but the printing costs are still significantly higher than with the FDM process. In addition, the handling of the resin is far more complex than the use of filament, which is why the devices are only really useful for a few applications. More on this in the UV resin or plastic filament guide: 3D printers in comparison.

For some time now, larger resin printers have also been on the market. Technically, they do not differ from the smaller models. However, the price differences to the standard devices are enormous. The Anycubic Mono X (test report) with a space of 192 × 245 × 120 mm for around 500 euros is such a model. The Voxelab Proxima 8.9 4K (test report) is the second large resin printer that made it into the editorial office. It has an installation space of 192 x 200 x 120 mm and costs just under 600 euros.

Small printer

As a small FDM printer, we define devices with a maximum size of less than 20 × 20 × 20 cm. Due to their construction, these printers are compact and also fit on the desk or on the shelf. However, such printers often do without a heatable print bed, which limits the filament selection. If you want to process materials such as ABS or PETG, you have to look carefully. When using PLA, however, this is not a problem.

Due to the short process paths, only low mechanical loads act on the individual components and so the structure is often not very stable. An extreme example of this is the rickety Labists X1 (test report), which we cannot recommend despite the competitive price of less than 80 euros. Even with more massive models, the individual axles are often only attached to one side of the frame. If sensible components are used, this has no influence on the printing result, as we saw when we tested the Wanhao Duplicator i3 Mini (test report) or the Davinci Mini w + (test report).

If you only want to print small model building parts, figures or the like, you will also achieve your goal with a small installation space. However, a look at the price comparison shows that this is not reflected in the purchase price and that the small FDM printers are relatively expensive. The Wanhao Mini i3 with an installation space of 120 × 100 × 135 mm, for example, currently costs around € 170. Significantly larger printers are available for the same price.

Medium sized printers

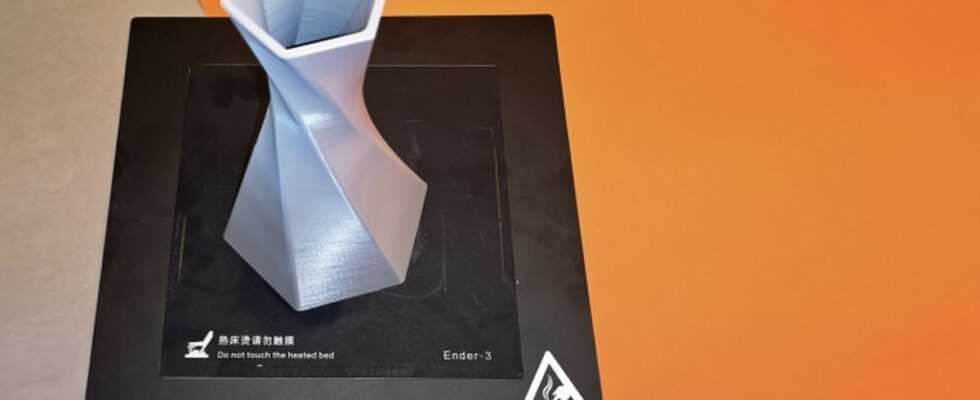

As medium-sized FDM printers, we define devices with an installation space of 20 × 20 × 20 cm up to 30 × 30 × 30 cm. This is the standard size and so most printers are available in this category. These include, for example, the Ender 3 models we tested (test report) and our price-performance tip Artillery Hornet (test report), which are available between 130 and 170 euros. Our FDM test winner, the Anycubic Vyper (test report), is available from around 350 euros. The external dimensions of such devices are, however, also significantly larger and so you should clarify in advance where you want to set up the printer.

If you don’t want to do handicrafts, you can also get ready-made devices in this size. Although these are immediately ready for use, they are significantly more expensive. For example, the Qidi X-Plus (test report) with a space of 27 × 20 × 20 cm costs 750 euros.

The printers of this size are usually more stable than the smaller printers. Due to the longer travel distances, the loads are also greater and so the axes are usually connected to the frame at two points each. The most widespread design of such printers are the so-called bed pushers. Here the print bed moves along the y-axis, while the print head is responsible for movements on the x- and z-axes. The devices in the XY core design, such as the Qidi X-Plus mentioned above, are somewhat more stable, but more expensive and larger.

In addition to the larger space available, the printers also offer a very good price-performance ratio. The popular Ender 3 or the Artillery Hornet, for example, are available for less than 150 euros. If you have enough space available, you should therefore always opt for the standard size instead of a mini printer.

Great printer

We call FDM printers large with a space of 30 × 30 × 30 cm or more. Like the tested Anet A8 Plus (test report), the A8 Plus or the Ender 3 Max, these are available from 245 euros and are therefore not much more expensive than standard-size models.

Devices such as the X5 SA Pro (test report) or Sapphire Plus (test report), which are available from around 300 euros, offer even more usable space (over 40 cm3). Since significantly more forces act on the components here, such large-capacity printers often use the so-called XY-Core design. Here the print head moves along the x and y axes, while the printing platform and heating bed move exclusively along the z axis. Although this construction is more complex and requires more space, it is also more stable, which in turn benefits the print quality.

In terms of price and features, such XL printers are very exciting. However, you should think carefully in advance whether you actually have enough space available for it. The external dimensions of such cars can easily reach 58 × 65 × 66 cm (Tronxy X5 SA Pro), which corresponds to about a large moving box.

Fully assembled printers with a large installation space are rare and very expensive. The Qidi X-Max (test report) with a space of 30 × 25 × 30 cm is not yet a real XL printer, but it already costs over 1000 euros.

Conclusion

The very high-resolution resin printers have the smallest installation space and the highest costs. Even cheap models are significantly more expensive than FDM printers when it comes to consumables, and are therefore only of interest in exceptional cases. If you don’t use the printer exclusively for detailed miniatures, you should use a filament printer. If it is a resin printer, we recommend the inexpensive Creality Halot One (test report) or the relatively large Anycubic Mono X (test report).

If there is enough space available, from our point of view it is always worth the small additional price to a large printer such as the Sapphire Plus (test report) or the Tronxy X5 SA Pro (test report). Extensive projects can then be implemented here without having to resort to glue.