Sales and earnings impacted

Engine problems at RTX are also dragging MTU down

September 11, 2023, 5:07 p.m

Listen to article

This audio version was artificially generated. More info | Send feedback

In the coming years, hundreds of aircraft will have to go into the workshop unscheduled. The reason is problems with the metal coating of the engines. The DAX group MTU is also involved in their production. He must first set his annual goals with reservations.

The material problems at business partner Pratt & Whitney are also having a massive impact on Munich engine manufacturer MTU. As a result, profits and sales could be one billion euros lower in the current financial year, MTU announced. Impacts on liquidity can also be expected in the following years up to 2026. Because of the material defects, Pratt & Whitney has ordered hundreds of additional engines back to the workshops, which is expected to cost $3 billion in the third quarter alone. The head of Pratt & Whitney parent company RTX, Gregory Hayes, said the problems with a powder metal were “frustrating” and are likely to have a “significant impact” on customers. Hundreds of aircraft have to be grounded due to additional maintenance.

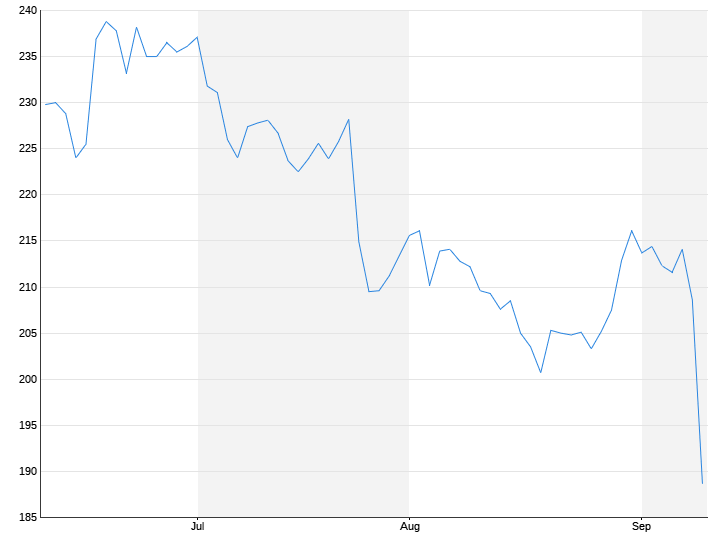

On the stock exchange, MTU shares lost a good twelve percent, RTX shares fell by more than five percent, and shares in aircraft manufacturer Airbus, which uses geared turbofan engines in its A320neo, fell by 1.3 percent. One trader said the magnitude was surprisingly negative.

MTU left it open how exactly the maintenance program would affect the forecast. However, the forecast for the current financial year is subject to reservations. “MTU will initiate measures with the aim of limiting the aforementioned impacts as best as possible.” As recently as July, MTU boss Lars Wagner spoke of the recall’s “moderate impact” on medium-term earnings expectations.

MTU has an 18 percent stake in the geared turbofan engine. GTF engines of the type PW1100G-JM are the most common engine for the Airbus successful A320neo model and are used by the low-cost airlines JetBlue, Spirit Airlines and Wizz Air, among others.

Wizz Air expects fewer capacities

The partner Pratt & Whitney, which is part of the RTX Group, had previously stated that 600 to 700 more workshop visits would be necessary in the coming years; Because of this, an average of 350 aircraft could not take off. Airlines usually receive replacement engines when their own engines have to go to the workshop – but the existing ones are not sufficient to recall the geared turbofan engines now affected. The airline Whiz Air said it expects its capacity to be reduced by ten percent in the second half of 2024.

The US group RTX estimated the financial burden for the coming years at up to 3.5 billion dollars. Both engines use powder metal, which can lead to inclusions. The affected high-pressure turbine disks should now be replaced. Hayes, for whom RTX is responsible, emphasized that there were production defects in the powder metal. In the meantime, the production process has been adjusted to rule out such contamination. Hayes said he was confident the issue was now resolved.

RTX said most of the engines would be revised this year and next. It is expected that the engines will have to stay in the workshops for an average of 250 to 300 days before they can be returned to the airlines. Originally, the company had expected a 60-day workshop stay. It might be a challenge to procure sufficient spare parts for the defective engines.