On the occasion of an American show dedicated to display technologies, a subsidiary of Chinese TCL presented the very first flexible 8K OLED screen having been manufactured using the inkjet process. An important technical advance for the industry.

TCL wants to advance an entire sector. At the end of May, during the Display Week 2023 trade show organized in Los Angeles, the Chinese manufacturer presented a rather special screen: the very first 65-inch, Ultra HD, 8K and flexible OLED panel having been manufactured using the process by inkjet (Ink‑Jet Printing). The process itself is not new, but its use on an OLED panel of this caliber is an industry first.

What is currently only a prototype has been designed by CSOT (Shenzhen China Star Optoelectronics Technology), the subsidiary of TCL dedicated to the manufacture of panels on behalf of TCL mainly, but also for other players. of the market, including Samsung, notes the specialized site AV Cesar. We can therefore imagine that this new production technique will subsequently benefit brands other than TCL.

The inkjet process, what interest?

The ccijOLED inkjet manufacturing process denotes the usual production technique, which relies mainly on evaporation processes. The organic materials are then deposited on a sheet of glass through a fine metal stencil, explains the specialized site OLED-Info. This process is effective, but could be improved, since it involves a significant loss in the materials deposited. Certain stages of this process also carry risks of contamination with dust, which can affect the production rate, and therefore the yields in the end.

OLED inkjet printing addresses many of these shortcomings by allowing precise deposition without the need to use the metal stencil discussed above. This technique also has the advantage of producing fewer parasitic particles, which increases yields. Still, it is more difficult to master, and the soluble OLED materials used for printing are less efficient than those which evaporate, we read. This leads to a lower density which further limits the use of this process to the manufacture of large screens (mainly for televisions).

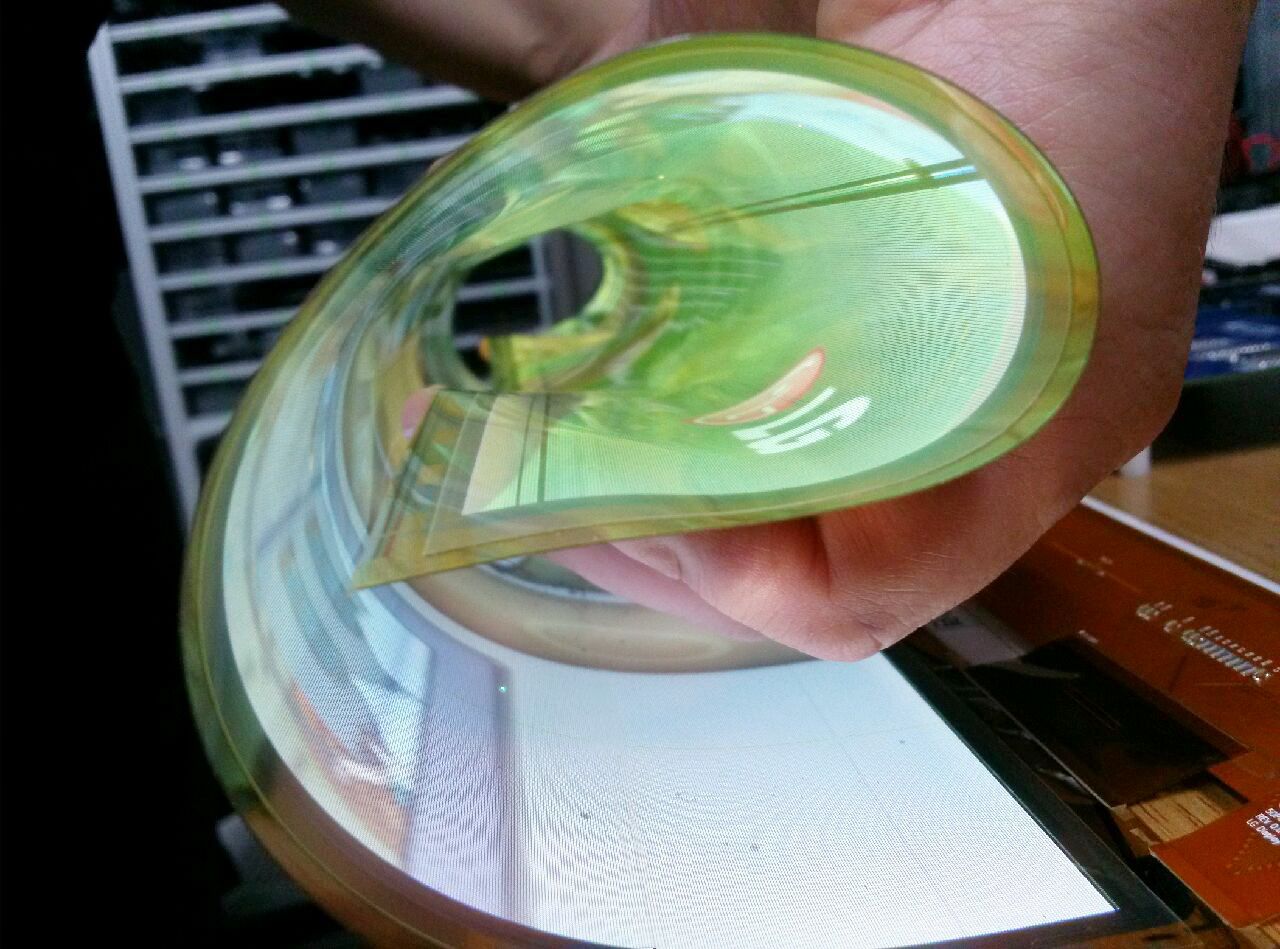

That’s good, that’s what TCL is looking for, which had already presented an OLED screen similar to the one unveiled at the end of May, but which was not flexible. The version that interests us today has the particularity of being able to fold in two on itself. And on the side of TCL, we obviously welcome this progress.

“The world’s first flexible 65-inch 8K inkjet-printed OLED display brings the industry’s largest flexible OLED foldable display to date, based on inkjet printing technology, with the higher resolution and 120Hz refresh rate“Commented a spokesperson for the brand quoted by AVCesar, before mentioning a”bend radius less than 25mm and a bend life of up to 100,000 bends“.

To follow us, we invite you to download our Android and iOS application. You can read our articles, files, and watch our latest YouTube videos.