Boucheron surprises with creations made from recycled asbestos waste: a radical approach that echoes the societal commitments of the house.

By Hervé Dewintre

© DR

Published on

Link copied

Copy link

Hélène Poulit-Duquesne hesitated for a long time before speaking out on eco-responsibility. Yet it is a subject that she took to heart as soon as she arrived at the head of Boucheron in 2015: “We launched work on the sustainability [durabilité, NDLR] at a forced march and we really progressed very quickly with the support of the Kering group [groupe de la famille Pinault, propriétaire du Point]. The teams told me that we were under-communicating on these subjects when we were doing a lot of things, but I had a complex: above all, I didn’t want to do greenwashing or that we are accused of marketing. »

The sincerity of the approach was nevertheless proclaimed by the collections of Claire Choisne. Once a year, in July, the artistic director of the house revealed a collection of fine jewelry that scrutinized the very essence of durability by using the unsuspected poetry of unusual materials or by soliciting without reluctance the new resources of the industry. For the past two years, jewelry has also been affected by this experimental approach. “We did a series using jeans in the Quatre collection and last year we worked on holography with the Jack collection. The idea is to bring down on our icons – Quatre, Serpent Bohème and Jack – the permanent research that we usually exploit in fine jewelry. »

READ ALSOThe jewels of Paris – The time of brands

Redefining the contours of the precious

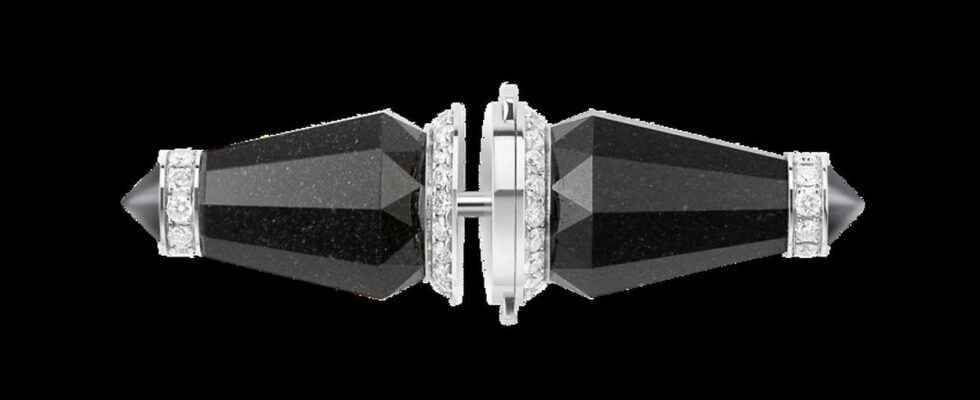

The house took another step forward this year by revealing – directly in jewellery, on its icon Jack – the fruit of a series of experiments. The innovation lies in the use of Cofalit. “Asbestos waste has two lives,” explains Claire Choisne. Either we bury them, which personally grips me and makes my heart ache, or we vitrify them, that is to say, we heat them to a very high temperature, between 1,400 and 1,600°C, which which renders them inert and harmless. They then become, thanks to the French company Inertam, which specializes in the treatment of asbestos, this ultimate waste that can no longer be recycled except to make road fill and which is called Cofalit. It is this last material that I wanted to work on. »

Complex work: Cofalit lacks the mechanical properties (resistance, solidity) allowing it to be used directly by craftsmen. Boucheron’s research and development unit, in conjunction with Sil (a Kering innovation group dedicated to jewellery) has therefore worked to set up a process allowing first of all to reduce this Cofalit to powder, then to redensify it by flash sintering : this emerging technique, already industrialized in Japan, is similar to conventional hot pressing and offers considerable technological advances in the fields of biomaterials, aeronautics and aerospace.

“It’s pure R&D: we grind the material to transform it back into powder, the grain of which we choose, which will influence its final appearance, and we redensify it: we obtain a block of solid material with mechanical properties close to ceramics. Each stage (at least five) required a specific industrial partner. A battery of tests, carried out by Inertam, Boucheron and then Kering’s Til (Test Innovation Lab), guarantees the harmlessness of this unprecedented material.

This challenge convinced Hélène Poulit-Duquesne to overcome her apprehensions regarding the public disclosure of the house’s commitments. For the past few days, an impact report, published on the site, bears witness to several years of action and in-depth work carried out, in particular on the origin of key raw materials. Difficult and long-term work, as the supply chains of metals and precious stones can be complex and opaque. Boucheron has nevertheless set itself an ambitious objective: full traceability of its main raw materials by 2025; these include gold, platinum, diamonds. Colored stones are also concerned: their supply will constitute the greatest challenge in terms of transparency since they come overwhelmingly, scattered all over the globe, from small artisanal mines where they are extracted before being exchanged, cut, polished and sold by changing hands several times.

READ ALSOHigh jewelry – The sense of celebration

“I braked with four irons before talking about durability. But what we have accomplished with Cofalit this year convinced me that we had reached the necessary level of maturity on these subjects,” concludes Hélène Poulit-Duquesne. A legitimacy attested by the decision taken in 2020 to attach the team dedicated to sustainable development directly to the CEO’s office. “Cofalit is more a philosophy than an innovation. The small amount we are going to produce is not going to save the planet. On the other hand, I hope to create a certain emulation, to invite reflection on this subject: how to exploit waste and make it valuable? Why not invent applications in design? We would love to see the fireplace that adorns this room in Cofalit, for example. It would be great if, in 10 or 15 years, sectors decided to reclaim this material and exploit it to give it a real second life. »