If electric cars from Kia and Hyundai are already very successful, an invention from the group promises an even crazier future. Thanks to the Universal Wheel Drive System, these two brands announce a great evolution of the wheel motor principle, with more than attractive possibilities. We go around.

Kia and Hyundai make excellent electric cars. Whether it’s the Niro, the EV6 or the EV9 at Kia or the Ioniq 5, Ioniq 6 and other Kona at Hyundai, it’s tested and approved: it’s a good job, particularly thanks to the 800 volt architecture high-end models allowing recharges in just 18 minutes.

The two brands, grouped together in the Hyundai group, are not stopping there. During the “Uni Wheel Tech Day” organized in Seoul, the group presented its work on a new technology,Universal Wheel Drive System. In theory, it heralds enormous advances in terms of the architecture of their next electric vehicles.

An evolution of a system studied several times…and abandoned

Let’s summarize. Today, electric cars use, roughly, the same architecture of a thermal car, with an engine which sends its power and torque to the wheels via a gearbox (replaced by a simple reduction gear in the majority of electric cars ) and gimbals.

Here, the Hyundai group has decided to take advantage of the compactness of electric motors to go further and allocate a small motor for each drive wheel. This is the principle of the “wheel motor”, which has already been studied on numerous occasions (notably by Michelin, but also by Lightyear and even by BMW), but systematically canceled: by inserting the motor directly into the wheel, this The latter became far too heavy and presented major defects in terms of comfort and handling of the equipped car.

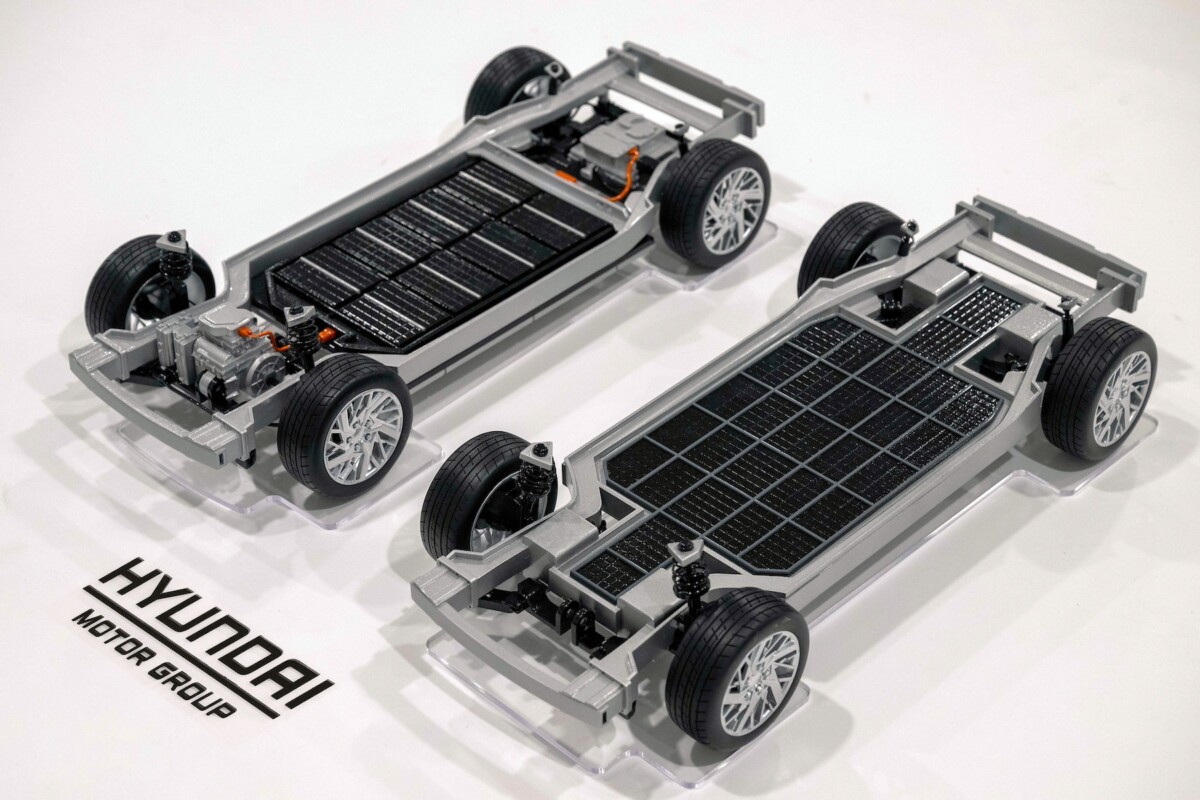

Here, the Korean group had the good idea of keeping the engine in the chassis, simply grafting the reduction gear into the wheel hub. And the least we can say is that the benefits are enticing.

Benefits galore

The number one advantage, according to the group, is obviously the space saving. Electric cars generally benefit from more interior space than a thermal car thanks to the compactness of their engines (this is why several of them, like Teslas, offer a second trunk in the before, the frunk), but this invention allows you to go even further.

Thanks to the miniaturization of the motors and the relocation of the reduction gear in the wheels, the available space increases drastically, opening up the field of possibilities. The freed space can thus make room for additional battery packs in order to increase autonomy, but we can also think about maximizing the interior space by guaranteeing a completely flat floor.

And that’s interesting in order to be able to develop new generation utility vehicles, which require as much space as possible, or even to think about new interior configurations with a view to 100% autonomous driving (even if we is still far away). In short, designers have free reign.

More efficient, more comfortable, more modular

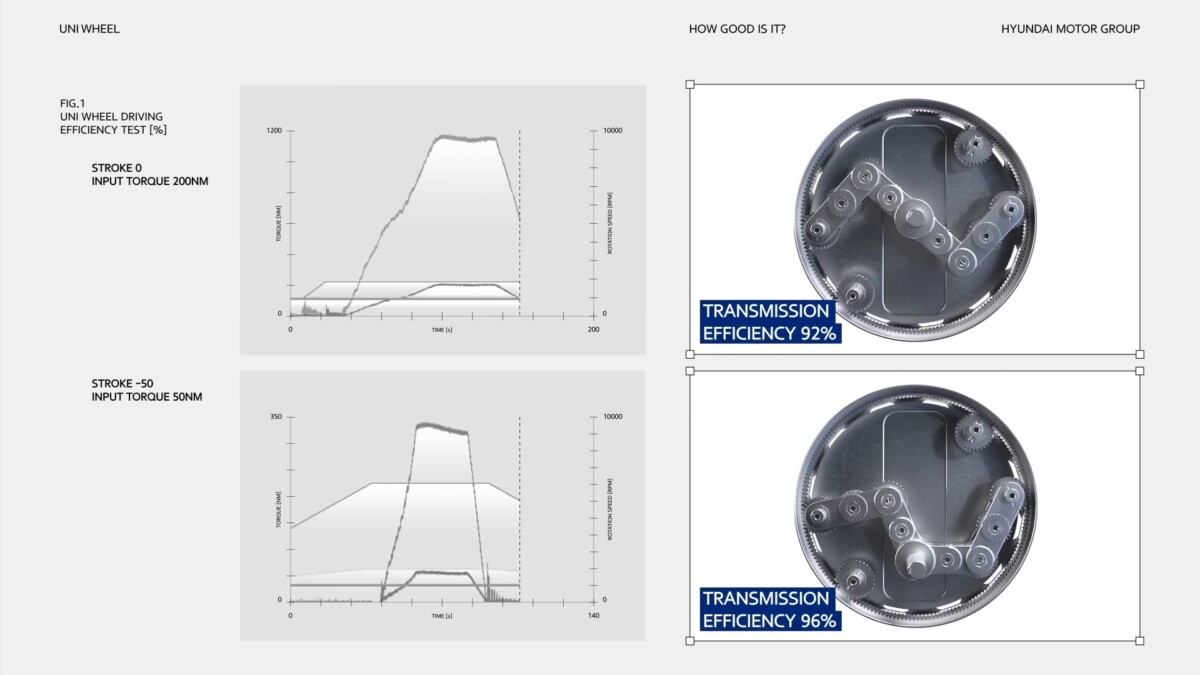

Other expected progress: those concerning driving itself. Thanks to the proximity between the motor and the wheel, efficiency losses are limited, thereby reducing consumption (and therefore, here too, increasing autonomy). For transmission efficiency, Hyundai announces a figure of between 92 and 96% depending on speed, but stable whatever the inclination of the wheel. We do not know the efficiency of the motor itself, but it is certainly greater than 90%, due to the electric motor.

For comparison, the efficiency of a heat engine is generally below 50% and it is impossible to adapt this type of technology to heat engines.

Comfort is not forgotten, since an air suspension is present to ensure first-rate body support in all situations.

As for more dynamic driving, there too, progress is present: the on-board electronics can calculate very precisely how much power to send to which wheel (what we call the torque vectoring) to benefit from sportier and more reassuring behavior. Knowing that the Korean group already knows how to make high-performance electric cars, as we saw after testing the Hyundai Ioniq 5 N.

Finally, this “Uni Wheel” is promised to be adaptable to many other applications. The technology can, in fact, fit into wheels ranging from 4 to 25 inches, enough to imagine derivatives in wheelchairs, bicycles or small delivery devices. An invention which therefore goes beyond the automobile market alone.

A probable arrival in Europe…but when?

Where the press release is less precise is on the mass arrival of this ultra-promising technology. No date has in fact been announced, the text simply specifying that the engineers “continue efforts to improve efficiency by adjusting the reduction ratio and improving the lubrication and cooling system”. Oh yes, eight patents have been filed in South Korea, as well as in the United States and Europe.

In any case, this is a more than tempting invention. We can’t wait to see this Uni Wheel arrive in series!