From Lower Saxony to the Ukraine

Rheinmetall weapons factory is running at full speed

06/08/2023, 2:13 p.m

The most important factory of the German armaments industry is located in Northern Germany. It is currently running at full speed because of the Ukraine war, especially in ammunition production. Old tanks are also processed. Business is going well for Rheinmetall.

In the middle of the Lüneburg Heath, 120-millimeter artillery shells with their black-painted tungsten tips are lined up in wooden crates awaiting transport to the Ukraine. In Unterlüß, the Düsseldorf group Rheinmetall maintains the most important industrial complex of the German armaments industry – and these days it’s very busy here. “We are ramping up the production of tank ammunition,” says plant manager Harald Weismüller. Machines, most of which are decades old, roar in the background. They are currently irreplaceable for the production of ammunition for Ukraine and for replenishing the stocks of NATO allies.

Rheinmetall is the largest European manufacturer of ammunition for tank guns, howitzers and other artillery pieces. The most important product: the 120-millimeter projectile for the Leopard 2 main battle tank. In January, the German government agreed to supply modern Leopard 2 tanks to Ukraine and also made it possible for other countries to send these tanks.

400-500 Leopard shells in one shift

In recent years, Rheinmetall has been producing around 60,000 of the 120 millimeter projectiles per year, but the production capacity has now reached 240,000. The plant currently manages 400 to 500 storeys per eight-hour shift, says Weismüller. “And we could increase that number.” With the takeover of the Spanish manufacturer Expal, the company has extended its market leadership in this area.

With the heavy 155 millimeter ammunition for the Panzerhaubitze 2000, for example, 40,000 projectiles have been manufactured per year so far. “But we could go up to 140,000,” says Weismüller. Ukraine is demanding further deliveries of guns and tanks from its western partners – and above all ammunition for them. This is pushing the production capacities in the EU to their limits. At the beginning of May, the EU Commission presented a 500 million euro plan to ramp up production. In this context, EU Industry Commissioner Thierry Breton also visited the armaments complex in Unterlüß. Weapons have been produced here for over 100 years. Rheinmetall leased the site as early as 1899.

Factory starts production line for cheetah ammunition

Recently, new machines have been added, for example to improve the milling of heavy cannons. New production lines are set up. “We integrate modern machines while we are in operation,” says Weismüller. For example, a highly automated production plant for 35-millimeter projectiles: The ammunition is intended for the anti-aircraft guns of the Gepard tank, the delivery of which to Ukraine Germany had already authorized in April 2022.

The new plant is to “produce the first storeys in less than six weeks,” says the plant manager. Initially, a capacity of up to 500,000 per year is planned. Until now, Rheinmetall has only manufactured cheetah ammunition in Switzerland. But the Confederation refuses to deliver to conflict zones like Ukraine. The construction of the production in Germany should avoid this problem.

In other halls of the Unterlüß industrial complex, old Bundeswehr tanks are dismantled in order to repair them, especially for use in the Ukraine. The traces of rust on many parts are evident. Also tested: A 15-kilometer long shooting range borders the site – the largest in Europe. That’s where the Leopard 2 cannons banged.

War fuels corporate profits

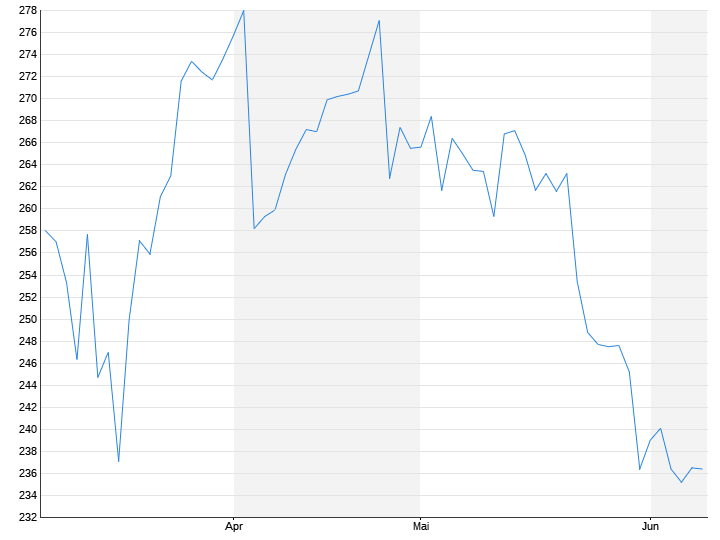

Rheinmetall employs 2,400 people in Unterlüß, and more are planned. Business could hardly be better for the group: In addition to direct demand from Ukraine, it also benefits from German rearmament and the billions for the Bundeswehr. The company’s share value has more than doubled since Russia’s attack, and its current backlog is three times its full-year 2022 sales.

In the spring, Rheinmetall rose to the Dax. The group also wants to produce directly in the Ukraine soon. Rheinmetall is preparing the repair of military vehicles in the country at war with the state-owned Ukrainian Ukroboronprom group. In a second step, new devices are to be manufactured directly on site.