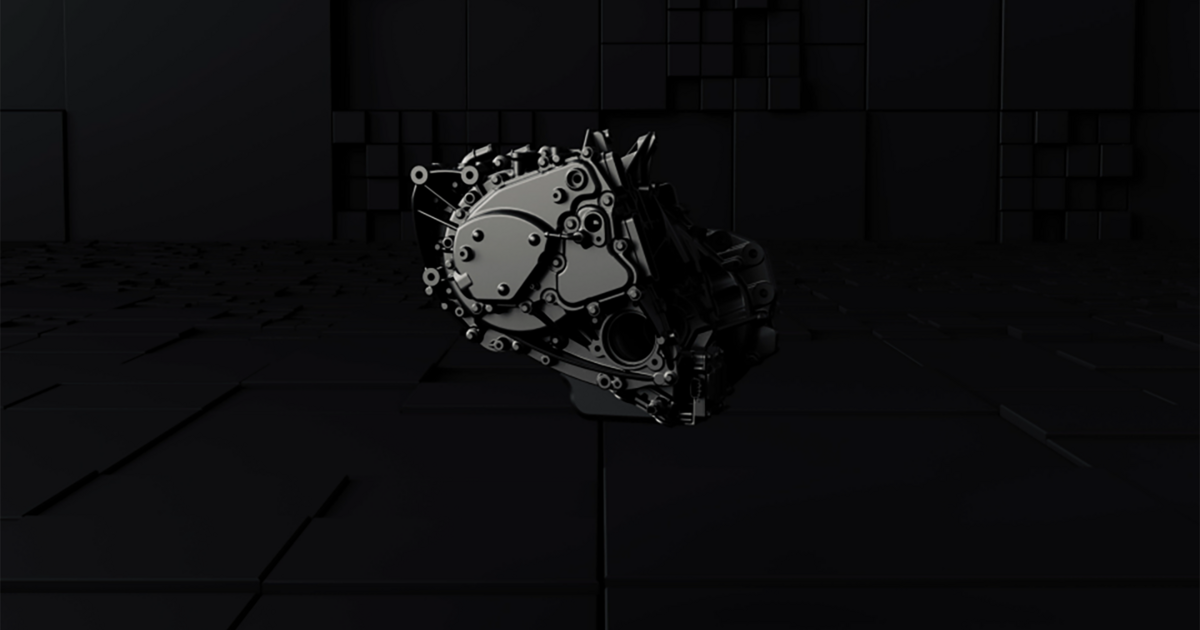

When two big names in the French automotive industry move forward hand in hand, this results in a significant innovation: the E7A engine which has been co-developed by Renault Group and Valeo since 2021. The two companies have joined forces using their expertise: the engine stricto sensu for Renault and the stator for Valeo. As a reminder, the stator of an electric motor corresponds to its fixed part which will produce the movement.

A rotor without rare earths

As early as 2012, Renaut designed and mass-produced one of the first synchronous wound rotor electric motors to equip the ZOE. This motor, which is based on EESM technology for Electrically Excited Synchronous Motor, has enabled the French company to acquire expertise at the very heart of the development of the E7A. This new generation benefits from an all-in-one architecture which allows it to be 30% more compact than the current engine of the Mégane E-Tech electric. Its rotor does not use rare earths, which allows this engine to have a carbon impact 30% lower than the current generation. In addition to the environmental issue, the absence of rare earths offers a certain security of supplies. Using a wound rotor instead of a permanent magnet system would significantly improve motor efficiency.

More powerful

The E7A is presented as a 3rd generation engine operating on a system voltage of 800 volts, double that found on current electric Renaults. This voltage should have an immediate impact on the recharge time which should be significantly reduced. In addition, the power of the E7A will take advantage of the new stator supplied by Valeo to achieve an increasing power level. The power of 200 kW is mentioned against 160 kW for the most powerful Renault Megane E-Tech.

This new engine is in development today. Its large-scale production is planned for the end of 2027 in the emblematic Cléon factory of Renault Group.