All-electric has its corollary: the question of batteries produced in large numbers and driving many product categories, from smartphones to wearables through cars, bicycles and motorized two-wheelers. The European Parliament has been considering their case since 2020, since it wishes since then to regulate its use and, above all, to limit the resulting waste. “Global battery demand is expected to increase 14 times by 2030 and the EU could account for 17% of this demand”he explains.

After two and a half years of work in the European Parliament, a complete directive has therefore just been adopted. It obviously concerns the batteries of electric vehicles and, more generally, those beyond 2 kWh, which will have to benefit from clear labeling indicating in particular their carbon footprint.

It also imposes collection rates for used batteries. The latter must, for example in the case of light electric vehicles (scooters, etc.), reach 51% in 2028 and 61% in 2031, while the batteries of products such as smartphones must be taken back at 45% this year, 63% in 2027 and 73% in 2030.

Europe also legislates on the proportion of recycled materials included in batteries. Within eight years, it requires that at least 6% of the cobalt, 85% of the lead, 6% of the lithium and 6% of the nickel used come from reuse. These rates should rise to 26% for cobalt, 12% for lithium and 15% for nickel five years later.

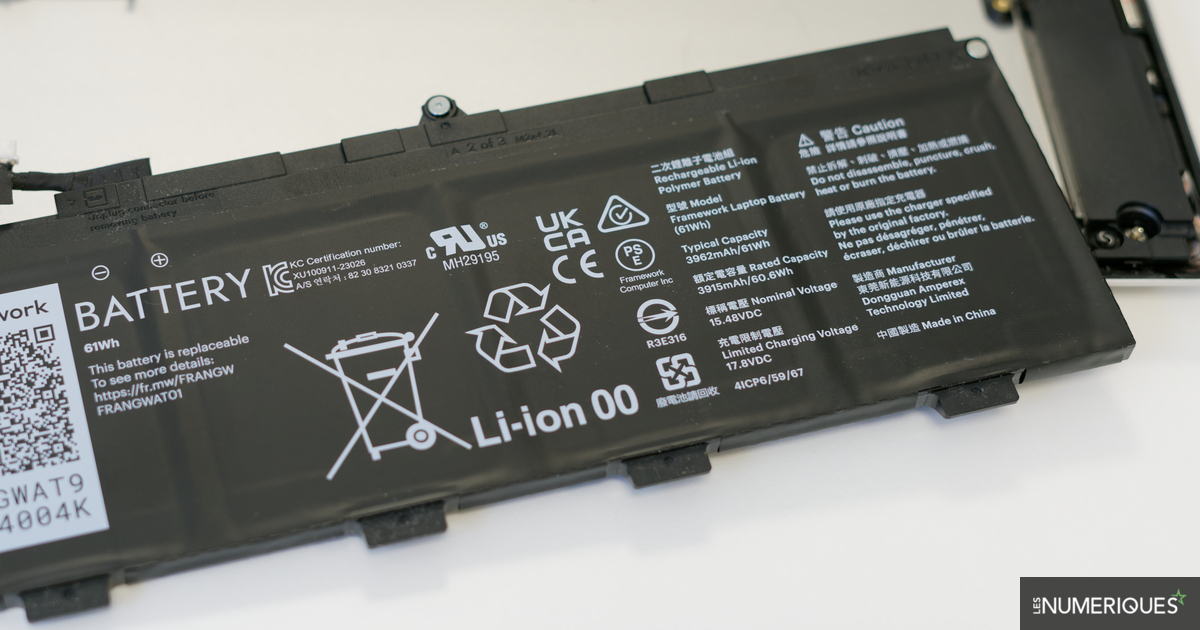

The provisions adopted by the European Parliament include a final rule which should not be without impact on product design. Because the manufacturers will have to make sure to facilitate the replacement of the “portable batteries”, that is, included in smartphones, tablets and other computers. Consumers should be able to replace them themselves.

Replacing smartphone batteries “easier”

The means to be implemented to achieve this objective are not detailed. This can therefore both mean that in the era of one-piece products, whose design requires complex manipulations to access their battery, the industry will have to allow the user easy access to the internal components of their terminals, yet very often glued to guarantee a perfect seal, sometimes sanctioned by an IP standard.

More likely, it will be to provide easy access to spare parts for battery-powered products, which are often difficult to obtain, but also complete documentation for installing them yourself. The idea remains to increase the lifespan of products equipped with batteries, without compromising the quality of their design, and therefore their durability.

While removable batteries were the norm until the mid-2010s, manufacturers abandoned detachable rear covers, often made of plastic, in favor of fixed glass or metallic shells. However, some initiatives, such as that of the firm Fairphone, whose smartphones are modular, prove that it is possible to combine removable battery and water resistance, the Fairphone 4 being itself IP54 certified (against splashes of fine water drops). Others, like Nokia for its G22, rely on certified repair kits to allow their customers to increase the life of their mobile devices.

Remember that the directive dedicated to batteries is not the first European decision aimed at increasing the durability of mobile products – which also depends on the solidity of the products and software maintenance. Just a year ago, the European Commission opted for the standardization of charging sockets, imposing the use of USB-C on smartphones, tablets, portable cameras and other small electronic devices, in order to limit the proliferation cables and chargers.