In recent years, you may have had to talk about “by wire” on certain elements of more or less recent cars. Behind the wheel, these technical notions are, most of the time, imperceptible, however, technically speaking, it brings a lot of advantages.

The automobile industry is a world in perpetual evolution, and even if it is generally “slower” than certain other industries, starting with that of smartphones or even connected objects, the evolution of the automobile in the space of a few decades can make you dizzy.

So of course, automotive is one of the most regulated industries in the world, which explains in particular a slower evolution compared to others. The most glaring example is undoubtedly Tesla’s semi-autonomous driving, at the cutting edge five years ago and today almost relegated to second place due, in particular because of safety standards that are sometimes very ( too much?) restrictive.

Each technological development in a car, especially when it concerns user safety, is subject to analysis by the legislator. To experiment with these new features, the best laboratory is obviously motorsport, and the technology that we are going to talk to you about today, namely the system brake by wire, was tested in Formula 1 before becoming “democratic” on some of our modern cars.

Finally, this last statement is not entirely true. In fact, you have to go back to the early 2000s to have a flange of this “electronic” braking system. This coincides with the debut of hybrid cars. And who was the pioneer of the hybrid car at that time? Toyota.

It was therefore in 2001 that the Japanese firm introduced the system “Electronically Controlled Brake” (ECB) in the Estima and Alphard, a minivan for the first, a van for the second, two models that we have never seen in France. This system marked, as it were, the beginning of a revolution in terms of compactness and precision of braking pressure regulation thanks to an electro-hydraulic approach.

However, it took several years before it became popular, and especially before manufacturers developed this system on a larger scale and without a hydraulic system.

The basic principles of braking “by wire”

The mechanics of a car’s braking system typically rely on a hydraulic system, where fluid-filled lines transmit the pressure generated by the operation of the brake pedal.

This pressure is then used to press down on the brake pads, causing them to rub against the rotors and slowing the vehicle. However, with the advent of IBS braking (Integrated Brake System), the engineers looked at some developments.

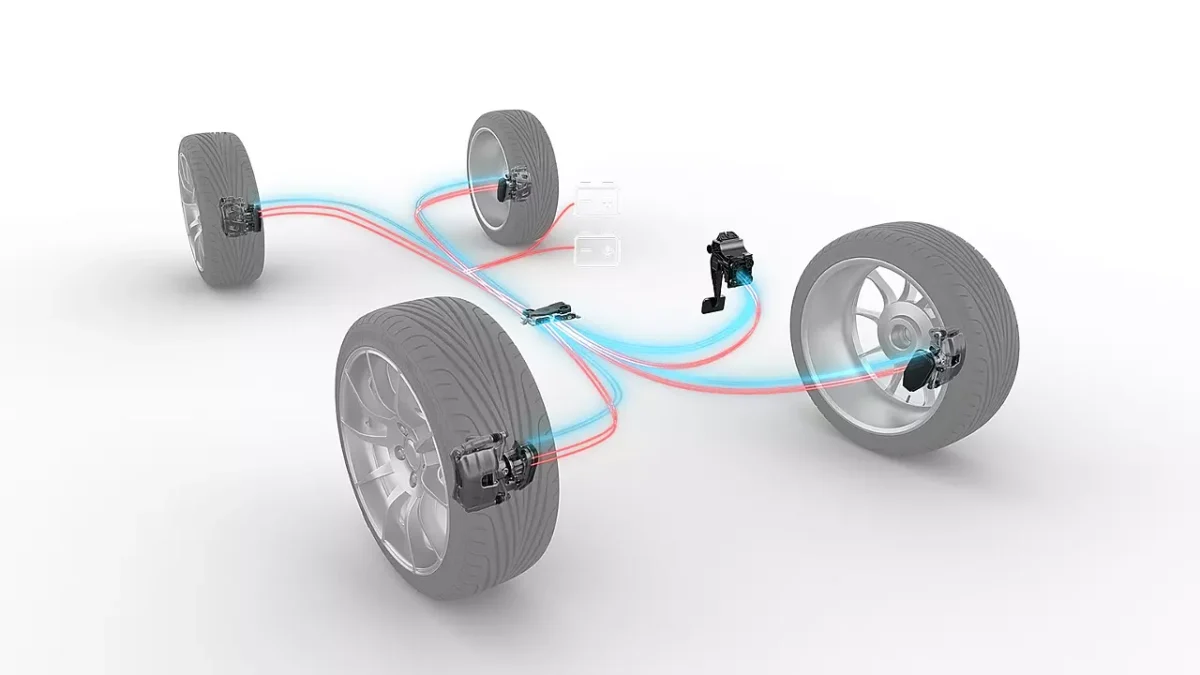

Although the system still retains its hydraulic aspect, the direct connection between the brake pedal and the hydraulic circuit is replaced. In modern systems, the pedal functions essentially as a “syringe”, connected to a potentiometer rather than a hydraulic master cylinder.

Technically, this potentiometer tells the ECU how deep the pedal is depressed, allowing the electro-hydraulic module controlled by the ECU to take over braking by adjusting the pressure for each wheel, depending on the force exerted on the pedal. In other words, the brake pedal acts more like an electronic interface.

This approach is reminiscent of the operation of a game pedal in a video simulator. Instead of a direct connection, the computer controls an electro-hydraulic module, thus triggering the appropriate braking pressure for each wheel. Hydraulic fluid is routed to the ABS/ESP box, where pressure distribution and regulation are managed.

Basically, this system must offer more precise and efficient braking depending on the force applied to the pedal. In fact, it’s a little different, because there were a few misses…

The importance of motorsport

There were some failures in particular on some of the cars sold, with difficult braking. There was also some in Formula 1, which also served as a bit of an open-air laboratory for this technology.

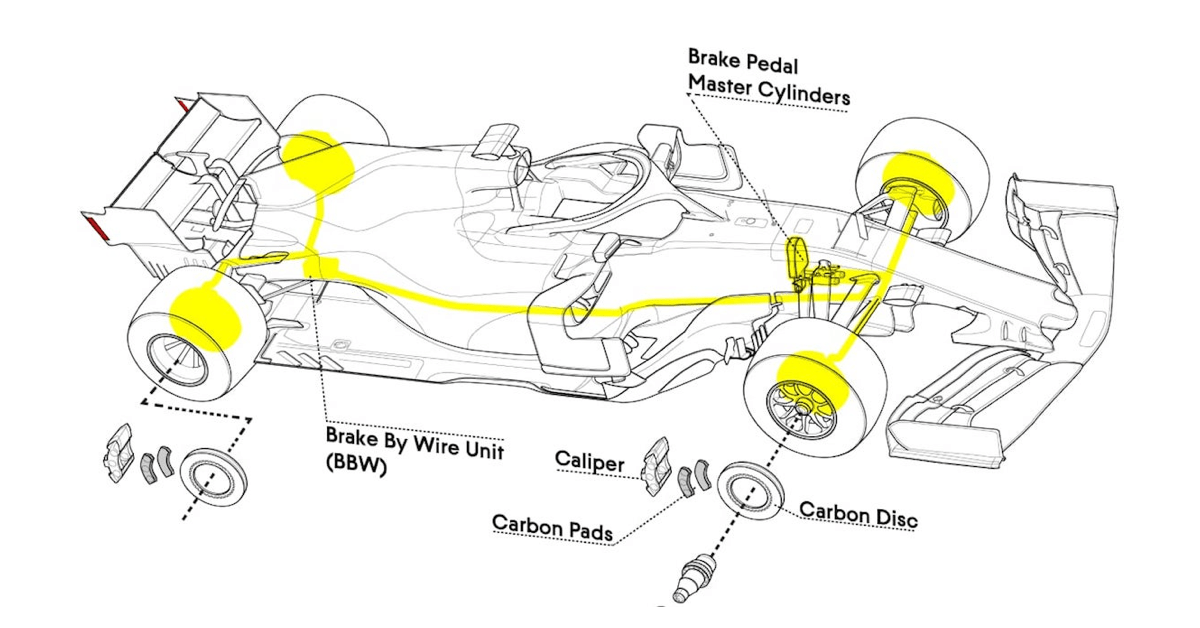

On Formula 1 cars, the rear braking system has similarities with that of the front brakes, but with one particularity: the potentiometer is made up of a mini hydraulic circuit. In summary, the brake pedal is connected to a master cylinder which generates pressure in a closed circuit. This pressure is measured by a sensor, which transmits the information to the computer.

The computer then takes control of an actuator located on another hydraulic circuit, specific to the rear braking system. This configuration is similar to the IBS system previously explained, with the notable difference of the mini hydraulic circuit dedicated to the rear brakes.

Let’s go back ten years in F1, to the “good times” some would say, when a certain Lewis Hamilton crushed the competition. Aficionados may remember the 2014 edition of the Canadian Grand Prix, where the two Mercedes F1 cars (driven by Lewis Hamilton and Nico Rosberg) suffered from an MGU-K failure (for Motor Generator Unit Kinetica kind of regenerative brake which converts kinetic energy into electricity, editor’s note), which caused Lewis Hamilton’s rear discs to rupture and his retirement.

In 2015, at the end of the Bahrain Grand Prix, both Mercedes suffered a simultaneous electronic braking system failure, caused by adjustments intended to improve tire performance. The cut of “brake by wire” deprived the Mercedes drivers of all braking power.

Advertised like this, one might believe that this system does not present many advantages. However, we can imagine that if it is used in Formula 1, where the objective is to go faster and faster (and therefore, paradoxically, to always brake better…), the system brake by wire has many advantages.

The advantages (and disadvantages) of brake by wire

This system has several significant advantages over traditional braking systems. First of all, it is lighter and less bulkywhich makes vehicles lighter (and therefore more fuel efficient) and reduces construction costs by eliminating the need for components such as vacuum pumps.

The use of an electrical module for braking control provides increased finesse in the process, eliminating any interference from human foot pressure and allowing the machine to handle four-wheel braking more efficiently.

This system also facilitates the transition to autonomous vehicles because it isolates human controls from the braking process, thereby simplifying the overall system and reducing associated costs. Finally, the absence of vibrations in the pedal when activating the ABS improves the driving experience.

For electric and hybrid cars, this also makes it possible to more finely balance the mix between regenerative braking, controlled by electric motors, and “mechanical” braking, which is handled by the brake pads and discs.

This is all well and good, but sports driving enthusiasts do not necessarily share the same opinion and report on certain models which are equipped with it. a certain lack of feeling and feedback. A problem similar to that encountered when switching from hydraulic power steering to versions “steer by wire”which for example carries the Tesla Cybertruck.

Who uses the brake by wire Today ?

If there are more advantages than disadvantages, we imagine that everyone uses it? If the equipment manufacturers offering directions “by wire” multiply, those working on braking without hydraulic connection are fewer : Hella, Brembo, Continental, ZF or even Hitashi for the Japanese.

Even if there were beginnings in 2001 with Toyota, the first braking systems by wire really saw the light of day at the same time as their introduction to Formula 1 at that time, i.e. in 2014. Bosch presented the “iBooster” system at the end of 2013, Continental in turn launched the “MK C1” in 2016.

On the thermal side, there is Alfa Romeo with its very popular Giulia which uses this system (in a very good way), while Chevrolet and its Corvette C8 has also been able to be seduced.

And on the electric car side too, again at the high end with Audi and its e-tron Sportback, Porsche and its Taycan and Tesla.

Let us note all the same that the regulations (still them) imply, particularly in Europe, maintaining an electro-hydraulic system in redundancy, if ever the system “by wire” was about to let go. It would indeed be unfortunate to end up with a car whose brakes no longer respond.

Did you know ? Google News lets you choose your media. Don’t miss Frandroid and Numerama.